Asphalt Pavement Material Specifications | Asphalt Cement | Asphalt Paving Specifications:

In this Article today we will talk about the Asphalt Concrete Pavement Material Specifications | Asphalt Cement | Asphalt Concrete Mixtures | Crushed Aggregate Base | Asphalt Paving Specifications | Asphalt Job-Mix Formula Tolerance.

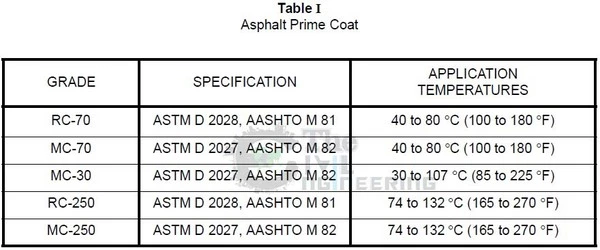

Asphalt Prime Coat:

The grades, specification references, and application temperatures for the liquid asphalt primer are given in Table I. The grade used shall be as dictated by local conditions and shall be approved by Client.

Sand:

Sand cover shall be clean, granular, mineral material meeting the following grading requirements. When tested with laboratory sieves, 100 percent shall pass the 4.75 mm (No. 4) sieve and from zero to 2 percent shall pass the 75 micron (No. 200) sieve.

Asphalt Cement:

Asphaltic cement shall be prepared from petroleum. It shall be uniform in character, free from water and shall not foam when heated to 175 °C (350 °F). It shall meet Grade 60-70 in conformance with either ASTM D 946 or AI SS-2 and SASO SSA 915.

Tack Coat:

The tack coat shall be applied between the asphalt base course and the surface course using liquid asphalt. Grade RC-70 (cut-back) meeting the requirement of AASHTO M 81.

Oiling of crushed aggregate bases shall be applied directly to the approved compacted base using liquid asphalt. Grade MC-70 (cut-back) meeting the requirement of AASHTO M 82.

OTHER POSTS:

-

Method Statement for Asphalt Paving Works | Asphalt Concrete

-

Method Statement for Concrete Repair Works | Structural Works

-

Method Statement for Excavation Compaction and Backfilling | Civil Works

Aggregate:

- The mineral aggregate for the surface course mixture shall be crushed stone, crushed gravel, crushed slag, sharp-edge natural sand, mineral filler, or a combination of two or more of these materials. Fifty percent by weight of the combined coarse aggregate, other than naturally occurring rough-textured aggregate, shall consist of crushed pieces having one or more faces produced by fracture.

- Crushed, coarse aggregate is defined for the purpose of this specification as material passing a 50 mm sieve and retained on a 2 mm (No. 10) sieve.

- Fine aggregate is defined as material passing the 2 mm (No. 10) sieve and retained on the 75 micron (No. 200) sieve.

- Filler is defined as material passing the 75 micron (No. 200) sieve. If filler in addition to that naturally present in the aggregate is necessary, it shall consist of thoroughly dry stone dust, volcanic ash or Portland cement. As delivered to the mixer, it shall be free from lumps of loosely bonded aggregations. The use of up to one (1) percent of hydrated lime may be used in the mix, particularly with aggregates that are subject to stripping. Fly ash shall not be used as filler. Mineral filler shall meet the requirements of ASTM D 242.

- If steel slag aggregates are used to make asphalt concrete, no aggregates greater than 4.75 mm (No. 4 sieve) shall be used in the mixture. Up to 50 percent of the material passing the 4.75 mm (No. 4) sieve may consist of iron blast furnace slag aggregates or natural aggregates or a combination thereof. The rate of feed of each type of aggregate shall be maintained within 20 percent of the amount set. Adequate means shall be provided for controlling and checking the accuracy of the feeder.

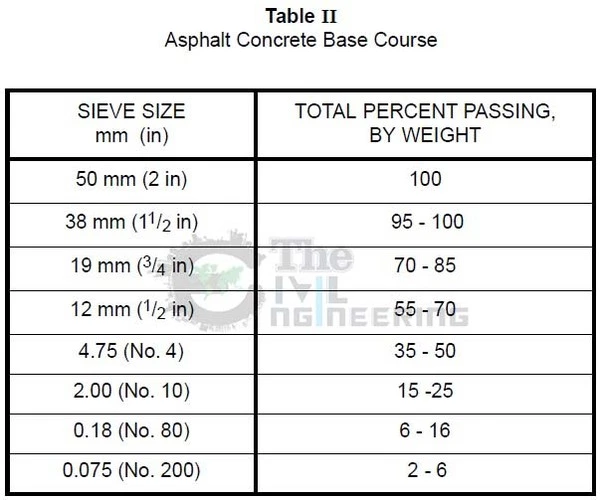

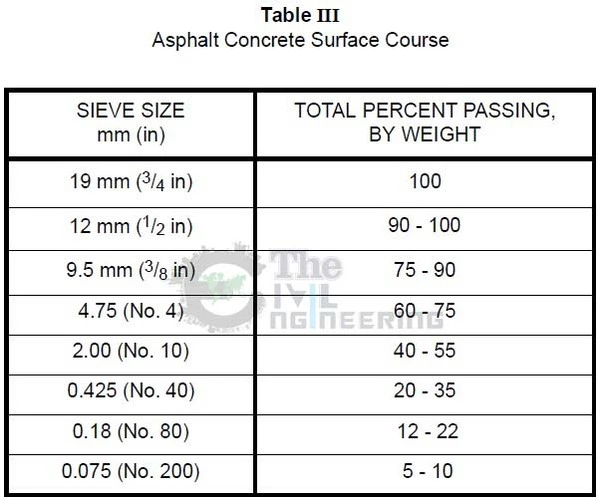

Asphalt Concrete Mixtures:

Dense Asphalt Concrete Base and Surfacing

The asphalt concrete mixtures shall consist of a uniform mixture of coarse crushed aggregate, fine aggregate, mineral filler and asphalt materials. The combined aggregates, including filler, shall meet the requirements of the following gradation using methods detailed in ASTM C 117 and C 136. Gradations conforming with AASHTO T 11 and T 27 specifications will be acceptable with Client approval.

Asphalt Concrete Base Course | The job-mix formula for the asphalt concrete base course mixture shall be within the limits of Table II. Asphalt content shall be between 5.0 and 7.0 percent by weight of total mix and the grade shall be as specified in asphalt cement.

Asphalt Concrete Surface Course | The job-mix formula for the asphalt concrete surface course mixture shall be within the limits of Table III. Asphalt content shall be between 5.5 and 7.0 percent by weight of total mix and the grade shall be as specified in asphalt cement.

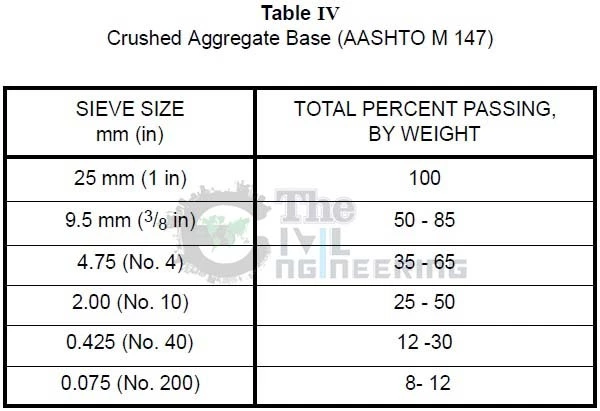

Crushed Aggregate Base.

The crushed aggregate base material shall consist of a uniform mixture of crushed coarse aggregate, fine aggregate and filler. The combined aggregates including the filler shall meet the requirements of the gradation in Table IV using methods described in ASTM C 117 and C 136.

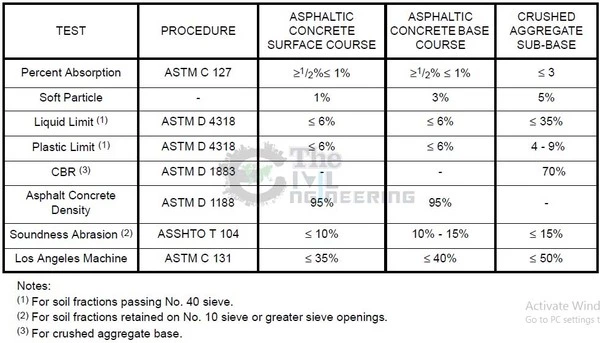

Quality Control of Materials | Quality control of the materials in various uses shall meet the limits of Table V.

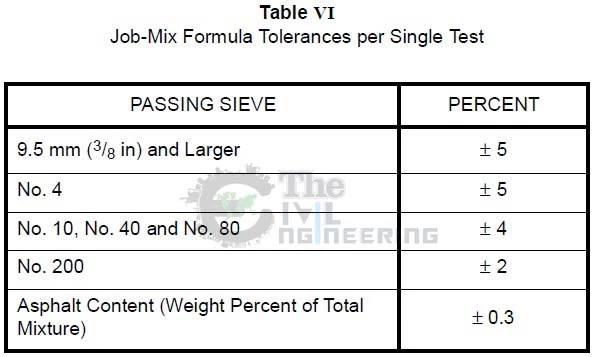

Tolerances for Job-Mix Formula | The tolerances for the job-mix formula shall be allowed per single test in accordance with Table VI.

Conclusion:

Full article on Asphalt Concrete Pavement Material Specifications | Asphalt Cement | Asphalt Concrete Mixtures | Crushed Aggregate Base | Asphalt Paving Specifications | Asphalt Job-Mix Formula Tolerance. Thank you for the full reading of this article in “The Civil Engineering” platform in English. If you find this post helpful, then help others by sharing it on social media. If you have any question regarding article please tell me in comments.

2 Comments

Very insightful. Keep up the good work !

Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar