Difference Between Flexible and Rigid Pavement | Flexible Pavement | Rigid Pavement | Types of Road Pavement

In this Article today we will talk about the Difference Between Flexible and Rigid Pavement | Types of Road Pavement pdf | Layers of Flexible Pavements | Requirements of Road Pavements | Failure of Flexible Pavements | Failure Criteria of Rigid Pavements | Classification of Rigid Pavements | asphalt road construction

Difference Between Flexible and Rigid Pavement:

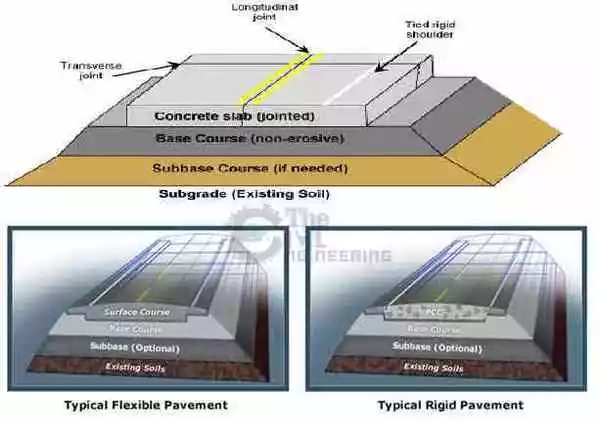

Flexible pavements can be defined as one consisting of a mixture of asphaltic or bituminous materials and aggregate placed on a bed of compacted granular material of appropriate quality in layers over the subgrade.

Rigid pavements are constructed from cement concrete or reinforced concrete slabs. Grouted concrete roads are the types of semi-rigid pavements.

What is Road Pavement?

A layered structure supported by the sub-grade soil to form the carriageway of the road is called a road pavement.

A highway pavement is a structure consisting of superimposed layers of processed materials above the natural soil sub-grade, whose primary function is to transmit the applied vehicle loads to the sub-grade. There two main types of road pavement used namely Rigid and Flexible Pavement.

The structure of pavement should be potentially strong to provide a good surface of acceptable riding quality, adequate skid resistance, favorable light-reflecting characteristics, and low noise pollution.

The main purpose is to confirm that the transmitted stresses due to the thrust load of wheels are sufficiently reduced so that they will not exceed the bearing capacity of the sub-grade.

There are two types of road pavements are generally recognized as serving this purpose, namely flexible pavements, and rigid pavements. Unsuitable design of pavements may lead to the early failure of pavements affecting the riding quality.

Requirements of a Good Types of Road Pavement

An ideal pavement should meet the following requirements and features:

- Sufficient thickness to distribute the wheel load stresses to a safe value on the sub-grade soil.

- Structurally strong to withstand all types of stresses imposed upon it.

- Adequate co-efficient of friction to prevent skidding of vehicles.

- Smooth surface to provide comfort to road users even at high speed.

- Produce the least noise from moving vehicles.

- The dustproof surface so that traffic safety is not impaired by reducing visibility.

- Impervious surface, so that sub-grade soil is well protected.

- Long design life with low maintenance costs.

Difference Between Flexible and Rigid Pavement

The following is difference between rigid and flexible pavement,

| Flexible Pavement | Rigid Pavement | |

|

1. Inflexible pavement deformation in the sub, the grade is transferred to the upper layers |

1. In Rigid pavement deformation in the the subgrade is not transferred to layers | |

| 2. Design is based on load distributing characteristics of the component layers | 2. Design is based on flexural strength or slab action | |

| 3. Flexible pavement has a low flexural strength | 3. Rigid pavement has a high flexural strength | |

| 4. Inflexible pavement, the load is transferred by grain to grain contact | 4. In Rigid pavement, no such phenomenon of grain to grain load transfer exists | |

| 5. Flexible pavement have low completion cost but repairing cost is high | 5. Rigid pavement have low repairing cost but completion cost is high | |

| 6. Flexible pavement have a low life span | 6. Rigid pavement life span is more as compared to flexible | |

| 7. Inflexible pavement surfacing cannot be laid directly on the subgrade but a sub base is needed | 7. In Rigid pavement, the surfacing can be directly laid on the subgrade | |

| 8. In Flexible pavement, no thermal stresses are induced as the pavement can contract and expand freely | 8. In Rigid pavement thermal stresses are more vulnerable to be induced as the ability to contract and expand is very less in concrete | |

| 9. That’s why expansion joints are not needed in Flexible pavement | 9. That’s why expansion joints are needed in Rigid pavement | |

| 10. In Flexible pavement strength of the the road is highly dependent on the strength of the subgrade | 10. In Rigid pavement strength of the road is less dependent on the strength of the subgrade | |

| 11. Rolling of the surfacing is needed in Flexible pavement | 11. Rolling of the surfacing is not needed in Rigid pavement | |

| 12. The road can be used for traffic within 24 hours in flexible pavement | 12. The road cannot be used until 14 days of curing in rigid pavement | |

| 13. In flexible pavement Force of friction is less Deformation in the subgrade is not transferred to the upper layers. | 13. In Rigid pavement Force of friction is high |

Difference between Flexible and Rigid Pavement

Types of Road Pavements pdf

There are mainly two categories in which road pavements are classified:

- Flexible Pavements

- Rigid Pavements

1. Flexible Pavements:

Flexible pavements can be defined as one consisting of a mixture of asphaltic or bituminous materials and aggregate placed on a bed of compacted granular material of appropriate quality in layers over the subgrade.

Water-bound macadam (WBM) roads and stabilized soil roads with or without bituminous toppings are examples of flexible or bituminous pavements. It is one of the most used types of road pavement. Types of Road Pavement pdf

The design of flexible pavements is based on the principle that for a load of any magnitude, the intensity of a load diminishes as the load is transmitted downwards from the surface by virtue of laying over an increasingly larger area, by carrying it deep enough into the ground through the layers of granular materials.

The wheel load acting on the pavement will be disturbed to a wider area and the stress decreases with the depth. By taking advantage of this stress distribution characteristic in bituminous pavements, pavements normally have many layers.

Flexible pavements layers reflect the deformation of the lower on to the surface layer. The lower layers will have undergone lesser magnitude of stress and low quality material can be used. Flexible pavements are constructed using bituminous materials.

The following types of construction have been used in flexible pavements:

A) Conventional Layered Flexible Pavements

Conventional flexible pavements are uniformly placed layered systems with magnificent quality materials that are placed among the high wherever stresses are high and quality low-priced materials are placed in lower layers. Requirements of Road Pavements

B) Full-depth Asphalt Pavements

Fill-depth asphalt pavements are constructed by placing bituminous layers directly on the soil sub-grade. This is more preferable when there is high traffic and local materials are not available in the nearby market. Requirements of Road Pavements

C) Contained Rock Asphalt Mat

Contained rock asphalt mats are created by installing dense/open ranked combination layers in between 2 asphalt layers. Changed dense ranked asphalt concrete overlays on top of the sub-grade can significantly cut back the vertical compressive strain in soil sub-grade and cover from surface water. Requirements of Road Pavements

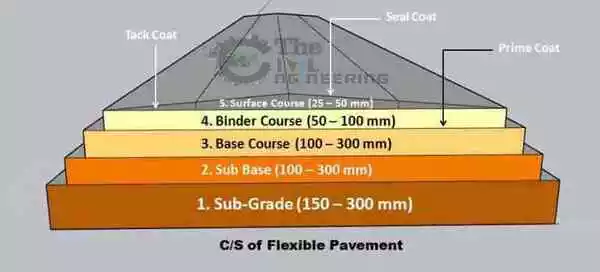

Typical Layers Of A Flexible Pavement

Layers forming flexible Pavements are-sub-base course, compacted sub-grade, natural sub-grade, seal coat, surface course, tack coat, binder course, prime coat, and base course. Flexible Pavement Layers are discussed below, asphalt road construction

Seal Coat

Seal Coat has the function to provide skid resistance to tyre and used to waterproof the surface hence friction could increase. Requirements of Road Pavements

Tack Coat

Tack Coat is usually used as the diluted asphalt emulsion as it is a very light application of asphalt. Bonding between two layers of binder course is provided by Tack Coat. Tack Coat should be applied thin, uniformly covering entire surface and should set as fast as possible.

Prime Coat

Prime Coat is is a form of low viscous cutback bitumen applied to the absorbent surface like granular bases on which the binder layer is placed. It also provides a binding between two layers.

It penetrates down into beneath layers then absorbent surface like granular bases on which binder layer is placed. Requirements of Road Pavements

Surface Course

The surface Course is directly in contact with the imposed load. Hence need to be composed of superior quality materials to withstand that load.

Dense graded asphalt concrete(AC) is used in its construction. It has the following functional characteristics,

- Characteristics such as friction, smoothness, drainage, etc. are possessed by Surface Course.

- It will prevent excessive quantities of surface water into the beneath layers.

- It is waterproof to resist distortion of Flexible Pavement layers.

- It must be tough to provide a smooth and skid-resistant riding surface and withstand imposed load. Failure of Flexible Pavements

Binder Course

The Binder Course provides an asphalt bulk concreting structure. It can also distribute the load to the base course.

It usually consists of aggregates having less asphalt and does not require high quality as the surface course. Therefore, replacement of a part of the surface course with the binder course might results in a more economical design.

Base Course

A layer of materials immediately beneath of surface binder course is none other than the Base Course, capable of additional load distribution and as well as contributes to the sub-surface drainage. Crushed stone, crushed slag, and other untreated or stabilized materials are its composition. Failure of Flexible Pavements

Sub-Base course

The primary functions of the Sub-Base course are to provide structural support, improvise drainage, and reduce the amount of intrusion of fines from the sub-grade in this pavement structure. It is situated beneath the base course. If the base course is open-graded, then the sub-base course with more fines can serve as a filler between sub-grade and the base course A sub-base course is not always needed or used. asphalt road construction

Sub-grade

This layer of the topsoil is prepared to receive the stresses from the layers above it. It is important that soil should not be overstressed at any instance. It must be well be compacted to the required density, near its optimum moisture content.

Failure of Flexible Pavements

- The major failures in the flexible pavement are fatigue cracking, thermal cracking, and rutting.

- The fatigue cracking occurring in the flexible pavement is mainly due to the horizontal tensile strain at the very bottom of the asphaltic concrete.

- The failure in flexible pavement occurs due to an allowable number of load repetitions because of tensile strain and this relation can be determined in the laboratory fatigue test.

- Occurrence of rutting is only on flexible pavements as stated by permanent deformation i.e. rut depth along with the wheel load path.

- Thermal cracking involves both the low-temperature cracking as well as thermal fatigue cracking. Failure Criteria of Rigid Pavements

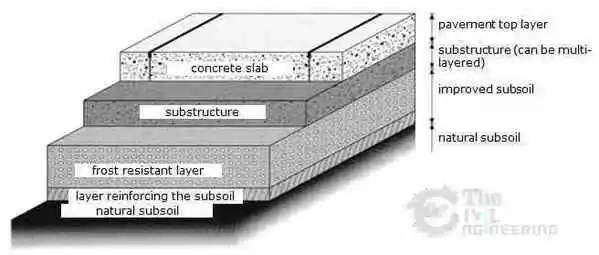

2. Rigid Pavements

Rigid pavement is constructed from cement concrete or reinforced concrete slabs. Grouted concrete roads are the types of semi-rigid pavements.

The design of rigid pavements is based on providing a structural cement concrete slab of sufficient strength to resists the loads from traffic. The rigid pavements have rigidity and high modulus of elasticity to distribute the load over a relatively wide area of soil. It is the most durable types of road pavement. Minor variations in subgrade strength have little influence on the structural capacity of rigid pavements in the design of rigid pavement, the flexural strength of concrete is the important factor but not considered as the strength of subgrade. asphalt road construction

Due to this property of pavement, when the subgrade deflects beneath the rigid pavement, the concrete slab is able to bridge over the localized failures and areas of inadequate support from subgrade because of slab action.

Rigid types of road pavement is made by Portland cement concrete and will be analyzed by plate theory than layer theory. Bending of the block due to wheel load and temperature variation and the ensuring tensile and flexural stress.

The followings are types or classification of rigid pavements: Failure Criteria of Rigid Pavements

A) Jointed Plain Concrete Pavements

Jointed plain concrete pavements constructed with closely spaced contraction joints. Dowel bars and aggregate interlocks are generally used for load transfer across joints. They normally have a joint spacing of 8 to 15m. asphalt road construction

B) Jointed Reinforced Concrete Pavements

Although reinforcements do not improve the structural capacity significantly, they can highly increase the joint spacing to 10 to 30m. dowel bars are required for load transfer. Reinforcements help to keep the slab together even after cracks appeared on the surface of concrete.

C) Continuous Reinforced Concrete Pavements:

In continuous reinforced concrete types of road pavements there is complete elimination of joints of reinforcement.

D) Pre-stressed Concrete Pavements

Pre-stressed concrete types of road pavement are designed and produced to be pre-stressed to bear tensile forces caused by external loads by various live objects such as vehicles on the roads or aircraft in the airports. asphalt road construction

As compared to asphalt pavements, pre-stressed concrete pavements are more resistance to airplane’s or vehicle’s wheel thrust and also it causes less wear and tear to themselves. This types of road pavement is also useful to minimize the maintenance cost.

Failure Criteria of Rigid Pavements

- Fatigue cracking has been the only reason or criterion for Rigid pavement design.

- The allowed number of load repetitions to initiate fatigue cracking is stress ratio dependent between flexural tensile stress occurring and concrete modulus of rupture.

- Pumping is identified as one of the important failure criterion for occurring of failure in rigid pavement.

- Pumping can be explained as the ejection of soil slurry through the joints and cracks of cement concrete pavement, which is caused during the downward movement of the slab under the heavy wheel loads at that instant.

- Some other major types of distress caused in rigid pavements include faulting, spalling, and deterioration. asphalt road construction

OTHER POSTS:

-

Compressive Strength Test of Concrete | Cube Test

-

Concrete Slump Test for Workability | Slump Test of Concrete

-

Thumb Rules Formula for Civil Engineers & Quantity Surveyors

-

Excavation and Backfill Specifications | Earthwork Inspection Requirement

-

Important Core Knowledge for QA/QC Civil Engineers or Inspectors

Conclusion:

Full article on Difference Between Flexible and Rigid Pavement | Types of Road Pavement pdf | Layers of Flexible Pavements | Requirements of Road Pavements | Failure of Flexible Pavements | Failure Criteria of Rigid Pavements | Classification of Rigid Pavements | asphalt road construction. Thank you for the full reading of this article in “The Civil Engineering” platform in English. If you find this post helpful, then help others by sharing it on social media. If any formula of BBS is missing from this article please tell me in comments.

2 Comments

Hi

Kindly contact me

Best regards

Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar