Compound Wall Estimate – A Step-by-Step Guide With Bar Bending Schedule

If you are planning a building project, it’s important to get an accurate estimate of how much the compound wall will cost. Using bar bending schedule to plan is a useful tool that not only helps with budgeting, but also enables you to have better control over your project. Its also help to prepare estimating and costing of earthwork excavation and block masonry construction cost of wall.

What is Compound Wall?

A compound wall for a building is a wall that surrounds the outside of a building or collection of buildings, like an apartment building or a campus of office buildings. It acts as a boundary between private property from public areas.

Its major function is to define the boundaries of the property and to give residents privacy and security. Depending on the level of security necessary, compound walls can be constructed from a variety of materials, including concrete, brick, stone, or wood. They can also vary in height and thickness.

Estimate of Compound Wall:

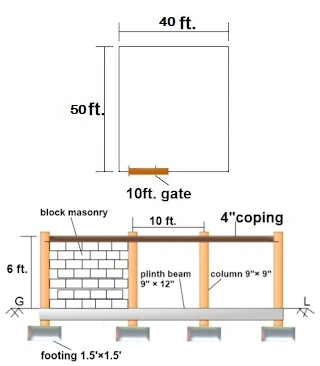

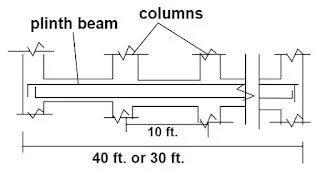

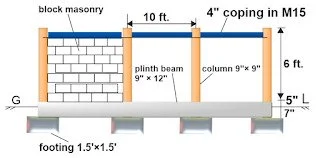

Let’s now calculate the price of a compound wall for a 40′ × 50′ site with a 10 ft gate as shown below:

Estimating and Costing of Compound Wall:

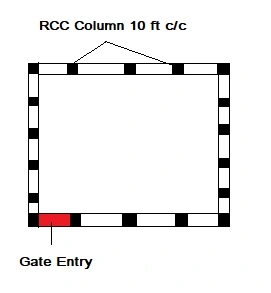

We have provided the RCC columns at 10 ft. c/c.

The No. of columns required

= site perimeter ÷ c /c column’s distance

= [ ( 50 ft.× 2 nos.) + ( 40 ft. × 2 nos.)] ÷ 10 ft.

= 180 ft ÷ 10 ft.

= 18 nos. ( as shown below.)

1. Earthwork Excavation for Compound Wall:

Excavation for the footing:

The number of excavation pit required for the rcc column footing = 18 nos.

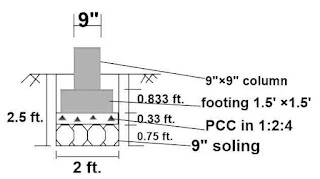

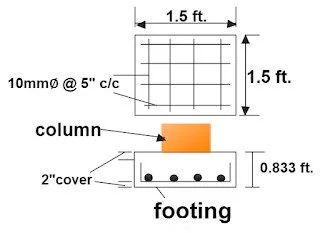

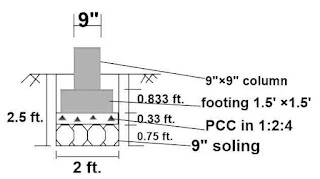

Let us provide 1.5 ft × 1.5 ft size footings, and the dimension of the pit to accommodate these footings shall be 2ft. × 2ft.× 2.5 ft. as shown in the drawing below.

The total volume of excavation for footing = Volume of Single Footing x Nos of Footings

= (2′ × 2′ × 2.5′) × 18 nos.

= 180 cft.

Excavation for the plinth beam:

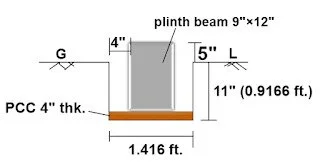

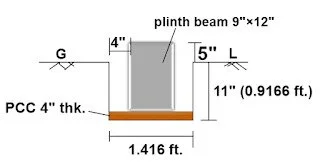

Let us excavate 4″ (inch) extra on both side of the plinth beam for formwork removal as shown in the drawing.

The volume of excavation for the plinth beam (RCC)

= [ perimeter of site – ( No. of footings × footing excavation width.)] × plinth excavation width × plinth excavation depth

= [180 ft. – (18 nos. × 2 ft.)] × 1.416 ft. × 0.9166 ft.

= 144 ft. × 1.416 ft. × 0.9166 ft.

= 186.90 cft.

The total excavation of earthwork for compound wall

= footing excavation + plinth excavation

= 180 cu ft + 186.90 cu ft.

= 366.90 cft.

2. Boulder Soling for Compound Wall:

Let us make a boulder soling of 9″ (inch) thick ( 0.75 ft.) for the footing as shown below.

The volume of soling for the footing = Volume of Soling per footing x No. of footings

= ( 2 x 2 x 0.75) × 18 Nos

= 3 cft × 18 Nos.

= 54 cft.

3. PCC for Compound Wall:

Let us prepare 4 inch thick ( 0.33 ft.) PCC bed for the footing & plinth beam.

volume of PCC for the footings:

The volume of PCC for the footings = Volume of PCC per footing x Nos of Footings

Vp1 = ( 2 ft x 2 ft x 0.33 ft) × 18 cft.

= 1.32 cft × 18 Nos.

= 23.76 cft.

As we know that the volume of excavation for the plinth beam is 186.90 cu ft.

From the above drawing, depth of excavation = 0.9166 ft.

PCC thickness = 4″ ( 0.33ft.).

Volume of PCC for the plinth beam

Volume of PCC for the plinth beam = X-Sec Area of PCC under Beam x [Beam Parameter – (Width of footing x Nos of Footings)]

Vp2 = (1.416 x 0.33) x [ 180 ft – ( 1.5 ft x 18 Nos)]

= 0.47 sft × 153 ft

= 71.91 cft.

The total volume of the PCC for the compound wall

= Vp1 + Vp2

= 23.76 cft.+ 71.91 cft.

= 95.67 cu ft.

Calculating the quantity of materials in PCC.

Let us make PCC (Plain Cement Conc.) in the 1:2:4 mix.

Quantity of cement bags required for PCC (Plain Cement Conc.)

= 17.942 bags × ( 95.67 cft ÷ 100 cu ft.)

= 17.16 bags.

The volume of sand required for PCC

= 44 cu ft. × ( 95.67 cft ÷ 100 cft.)

= 42.09 cft.

The volume of aggregates required for PCC

= 88 cu ft. × ( 95.67 cft ÷ 100 cft.)

= 84.19 cft.

4. Quantity of Materials in RCC Footings:

Let us make a RCC footing of size 1.5 ft × 1.5 ft. having 10″ ( 0.833 ft. ) thickness as shown in the drawing

Given data :

Footing length = 1.5 ft.

Width = 1.5 ft.

Thickness = 0.833 ft.

Rebar diameter = 10 mm.(0.0328 ft.),

Spacing = 5″ (0.416 ft. ) c/c

Cover = 2″ (0.166 ft ) on all the sides.

As we know that, the number of footings = 14nos.

4a. The volume of footing for the compound wall

= [total nos. × length × breadth × thickness]

= [18 nos. × 1.5 ft. × 1.5 ft. × 0.833 ft.]

= 33.74 cu ft. i.e. 0.95 cum.

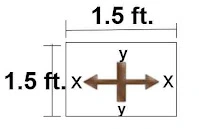

4b. BBS for the footings:

No. of bars along the x-axis

= [ {( footing length ) – ( 2 × cover )} ÷ spacing ] + 1

= [ {( 1.5 ft.) – ( 2 ×0.166 ft.)} ÷ 0.416 ft.] +1

= [ { 1.168 ft. } ÷ 0.416 ft. ] +1

= 2.807 +1

= 4 nos.

( By rounding off )

No. of bars along the y-axis

= [ {( footing width ) – ( 2 × cover )} ÷ spacing ] + 1

= [ {( 1.5 ft.) – ( 2 ×0.166 ft.)} ÷ 0.416 ft.] +1

= [ { 1.168 ft. } ÷ 0.416 ft. ] +1

= 2.807 +1

= 4 nos.

( By rounding off )

Cutting length of the bar along the x-axis

= [ {bar length in x-axis } + { 2 nos. × ( L – bend length)}] – 2nos. × ( 2 times bar dia. for 90° bend.)

( we have deducted 2 times bar dia i.e. 2d for the 90° bend of the bar. )

= [ { footing length – 2 × cover } + 2nos.×{ footing height – 2 × cover}] – 2× ( 2 × bar dia. )

= [ { 1.5 ft. – 2 × 0.166 ft. } + 2 × { 0.833 ft. – 2 × 0.166 ft. } ] – 2 × ( 2 × 0.0328 ft.)

= [ 1.168 ft. + 1.002 ft. ] – 0.131ft.

= 2.17 ft. – 0.131 ft.

= 2.039 ft. i.e. 0.6214 m.

Cutting length of the bar along the y -axis

= [ {bar length in y-axis } + { 2 nos. × ( L- bend length)}] – 2nos. × ( 2 times bar dia. for 90° bend.)

= [ { footing width – 2 × cover } + 2nos. × { footing height – 2 × cover}] – 2× ( 2 × bar dia. )

= [ { 1.5 ft. – 2 × 0.166 ft. } + 2 × { 0.833 ft. – 2 × 0.166 ft. } ] – 2 × ( 2 × 0.0328 ft.)

= [ 1.168 ft. + 1.002 ft. ] – 0.131ft.

= 2.17 ft. – 0.131 ft.

= 2.039 ft. i.e. 0.6214 m.

Note: The cutting length & number of bars in both ( x-axis & y-axis ) directions will be the same, in the case of square footing having a similar bar diameter.

Now, we will prepare BBS (Bar Bending Schedule) of the footing, from calculated data.

sl bar dia. no. length total weight total

no. type mm. in m. length in kg/m weight

1. x- axis 10 4 0.6214 2.4856 0.62 1.54

2. y – axis 10 4 0.6214 2.4856 0.62 1.54

Total weight of the bars = 3.08 kgs

Add 2 % wastage = 0.0616 kgs

A grand total of rebar for a footing = 3.1416 kgs.

Note : Weight of 10mm dia bar /meter is 0.62 kg.

The total weight of the 10mm dia bar for all the footings

= [18 nos. × 3.1416 kgs.]

= 56.55 kgs.

5. Quantity of Materials in RCC Plinth Beam:

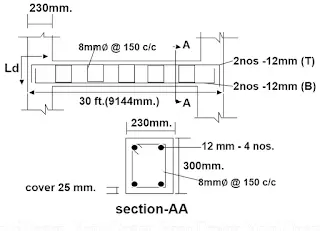

Let us make a 9″×12″ RCC plinth beam as shown in the drawing.

Given data :

Plinth beam size = 9″× 12″

Main bar dia = 12 mm., no. of bars = 4 nos.

Stirrups 8mm @ spacing 150mm c/c , clear cover = 25 mm from all the sides.

5a. The volume of plinth beam concrete

= length × breadth × depth

= [ (perimeter of site – no.of columns × column width) × breadth × depth]

= [(180 ft – 18 nos. × 0.75 ft.) × 0.75 ft × 1 ft.]

= [166.5 ft. × 0.75 ft. × 1ft.]

= 124.875 cu ft. i.e. 3.53 cum.

Note: We have deducted the column width from the plinth beam length, as we have included them in the column volume.

5b. BBS of plinth beam for the compound wall.

The perimeter of site = 180 ft. = 54864 mm.

We will provide Ld at the corner rcc columns of the compound wall, passing the plinth bar through the intermediate columns.

The cutting length of the main bar

= [ (perimeter of site) + (8 nos × Ld ) + (4 nos. × lap length) – (8nos × column width) ]

Note: we assume that one overlapping for each bar & we will provide a lap length of 50d.

Let us provide development length Ld = 40d for the main bar.

= [ (54864 mm.) + (8 nos. × 40 × 12mm) + (4 nos × 50 × 12 mm) – (8 nos.× 230mm)]

= [54864 mm + 3840mm + 2400mm – 1840mm ]

= 59264 mm. i.e. 59.264 m.

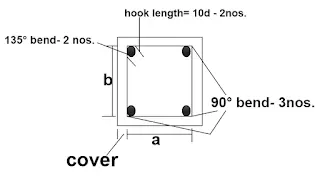

Cutting length of the stirrup

= 2 nos. × (a +b ) + hook length – 90° bend – 135° bend

Where a = beam width – 2 × cover, & b = beam depth – 2 × cover

= 2 nos. × [ ( 230 mm – 2 × 25mm.) + ( 300 mm – 2 × 25mm ) ] + (10d ) – (3 nos. × 2d ) – (2 nos. × 3d)

Here, 10d is taken for hook length.

We have deducted 2d for 90° bend – 3nos., & 3d for 135° bend – 2nos. as shown in the above drawing.

= 2 nos. × [ ( 180 mm ) + ( 250 mm ) ] + (10 × 8mm) – ( 3 nos. × 2 × 8mm ) – ( 2 nos. × 3 × 8 mm.)

= 2 nos. × [ 430 mm ] + 80 mm – 48mm – 48mm.

= 860 mm + 80 mm – 96 mm.

= 844 mm i.e. 0.844 m.

Number of stirrups

= ( length of the plinth beam ÷ stirrup spacing ) + 1

where Length of Beam = Parameter – (0.75 x No. of footings) = 180 – (0.75 x 18)

here, length of the plinth beam = 166.5 ft = 50749 mm

= ( 50749 mm. ÷ 150 mm) +1

= 338.33+ 1

= 339.33 nos.

By rounding off, the no. of stirrups required = 340 nos.

Now, let us prepare a BBS (Bar Bending Schedule) table for the plinth beam.

sl. bar dia. no. length total weight total

no. ( mm) (m.) length kg/m weight

1. main bar 12 4 59.264 237.056 0.89 210.98

2. stirrups 8 340 0.844 286.96 0.395 113.35

Total weight of bars = 324.33 kgs.

Add 2% wastage = 6.49 kgs.

Grand total of rebars = 330.82 kgs.

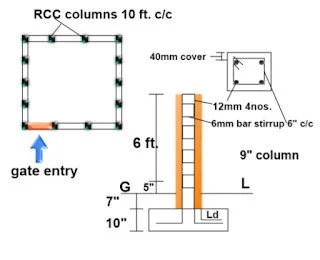

6. Quantity of Materials in RCC Column:

Let us make a rcc column of size 9″ × 9″ as shown in the drawing.

Given data :

Column height above GL = 6 ft.+ 5″(0.416 ft.) = 6.416 ft., below GL = 7″ (0.583ft.)

Size of Column = 9″ × 9″ (228.6mm × 228.6 mm )

Longitudinal bars 12mm (0.03936 ft.) – 4 nos, cover – 40mm.

Lateral ties dia d1 – 6mm @ 6″ (150 mm.) c/c

From part 1, number of columns = 18 nos.

6a. The volume of the column concrete for the compound wall

= total nos. × height × length× breadth

= total nos. × (height below GL + height above GL ) × length × breadth

= 18 nos. × ( 6.416 ft. + 0.583 ft. ) × 0.75 ft. × 0.75 ft.

= 18 nos. × 7 ft. × 0.75 ft × 0.75 ft.

= 70.875 cft. i.e. 2.0 cum.

6b. BBS of a column for the compound wall.

Length of the longitudinal bar

= above GL + GL to footing top + development length ( Ld )

= 6.416 ft. + 0.583 ft. + ( 50d )

( we have taken Ld as 50d, where d = bar diameter.)

= 7 ft. + (50 × 0.03936 ft.)

= 7 ft. + 1.968 ft.

= 8.968 ft. i.e. 2.733 m.

Length of the lateral ties

= perimeter of lateral ties + total hook length – no. of bends

= 2 sides × ( a – 2 × cover ) + 2 sides × ( b – 2 × cover ) +( 2nos × hook length) – (3 nos. × bend )

( Here, we have taken hook length = 10d1 for 135°∠ & bend = 2d1 for 90°∟)

={ [ 2 × (228.6mm – 2 × 40mm.) ] + [ 2 × ( 228.6 mm – 2 × 40 mm.) ] } + { 2 × 10 × 6mm } – {3 × 2 × 6mm }

={ [ 2 × 148.6 mm ] + [2 × 148.6 mm ]} + 120 mm – 36 mm.

= {297.2 mm + 297.2 mm} + 84 mm

= 678.4 mm i.e. 0.678 m.

Total number of lateral ties ( stirrups )

={ [ length of the longitudinal bar – Ld ] ÷ stirrup spacing } + 1

Note: Ld is deducted from the length, as no stirrups are provided over that length.

= {[ 2733 mm – (50 × 12 mm )] ÷ 150 mm.} + 1

= {[ 2733mm – 600mm ] ÷ 150 mm.} + 1

= {2133 mm ÷ 150 mm.} + 1

= 14.22 + 1

= 15.22 nos.

Rounding off, the number of stirrups required = 15 nos.

Now, let us prepare BBS (Bar Bending Schedule) for a column.

sl. bar dia. no. length total weight total

no. ( mm) (m.) length kg/m weight

1. longitudinal 12 4 2.733 10.932 0.89 9.729

2. lateral 6 15 0.678 10.17 0.22 2.237

Total weight of bars = 11.966 kgs.

Add 5% wastage = 0.5983 kgs.

Grand total of rebars = 12.564 kgs.

The total weight of bars for compound wall columns

= 18 nos × 12.564 kgs = 226.152 kgs.

7. Quantity of Materials for Estimating Block Masonry of Compound Wall:

Let us build this compound wall of 6″ (inch) thickness having 6 ft. height as shown in the drawing.

The total length of the compound wall

= site perimeter – gate length

= (50ft. × 2 nos.) + (40 ft. × 2 nos.) – 10 ft.

= 100 ft. + 80 ft. -10 ft.

= 170 ft.

The total length of the block masonry wall

= compound wall length – (no. of columns × width of a single column.)

= 170 ft. – (18 nos.× 0.75 ft.)

= 170 ft. – 10.5 ft.

= 156.5 ft.

Height of the block masonry wall

= compound wall height – coping thickness

= 6 ft – 0.33 ft.

= 5.67 ft.

7a. The volume of the block masonry

= length × height × thickness

= 156.5 ft. × 5.67 ft. × 0.5 ft.

= 433.68 cft.

Number of concrete blocks required

= 210 nos. × ( 433.68 cu ft. ÷ 100 cu ft.)

= 911 nos.

The number of cement bags required

= 1.038 bags × ( 433.68 cu ft. ÷ 100 cu ft.)

=4.501 bags.

The volume of sand required

= 7.634 cu ft. × ( 433.68 cu ft. ÷ 100 cu ft.)

= 33.12 cu ft.

Note: The above-given quantities are taken from the article “Calculating the quantity of materials in a 100 cubic ft. block wall.”

8. Quantity of Materials for Coping and Backfilling of Compound Wall

Let us make coping over block masonry work having 4″ (0.33 ft.) thickness in M15 grade.

8a. The volume of coping for the compound wall

= coping length × width × thickness

= block masonry length × masonry width × coping thickness

= 156.5 ft. × 0.5 ft. × 0.33 ft.

= 25.82 cu ft. i.e. 0.731 cu m.

Let us make this coping in M15 grade concrete.

The number of cement bags required for the coping work

=17.942 bags × (25.82 ÷ 100 cu ft. )

= 4.632 bags.

The total volume of sand required for coping

= 44 cu ft × (25.82 ÷ 100 cu ft. )

= 11.361 cu ft.

The total volume of coarse aggregates required

= 88 cu ft. × (25.82 ÷ 100 cu ft. )

= 22.722 cu ft.

Note: The above quantities for the calculation purpose is taken from “ Calculating the quantity of materials in 100 cu ft. & 1 cum. of M15 (1:2:4 ) grade concrete“.

8b. volume of backfilling for the compound wall

Volume of Backfilling for plinth beam

picture

= Volume of excavation for plinth beam – beam PCC volume – plinth beam volume up to GL.

= [(186.90 cu ft.) – (52.33 cu ft.) – (124.875 cu ft. × 0.583 ft ÷ 1 ft.)

( By volume ratio with plinth beam 👆)

= 186.90 cu ft. – 52.33 cu ft – 72.802 cu ft.

= 61.768 cu ft.

Backfilling for footing:

=[ volume of excavation for footing – {footing vol. – soling vol. – PCC vol. – column vol. up to GL.}]

= [180 cu ft.- {33.74 cu ft. + 54 cu ft. + 23.76 cu ft.+ ( 18 nos × 0.583 × 0.75 × 0.75) } ]

= [180 cu ft – 117.40 cu ft.]

= 62.60 cu ft.

The total volume of backfilling

= backfilling for plinth beam + backfilling for footing

= 61.768 cu ft. + 62.60 cu ft.

= 124.368 cu ft. i.e. 3.52 cum.

Overall Quantities for Construction Cost of Compound Wall:

First, we will sum up the total quantity of materials from all parts of this compound wall.

The volume of RCC for compound wall

= [for footings+ for plinth beam + for columns]

= [0.95 cum + 3.53 cum. + 2.0 cum.]

= 6.48 cum .i.e. 228.8 cu ft.

Let us make this RCC in M20-grade concrete.

The no. of cement bags required for RCC work

= [8.06 bags × ( 6.48 cum ÷ 1 cum )]

= 52.23 bags

The volume of sand required for RCC work

= [ 0.42 cum × ( 6.48 cum ÷ 1 cum )]

= 2.722 cum. i.e. 96.1 cu ft.

The volume of coarse aggregates required for RCC work

= [0.84 × ( 6.48 cum ÷ 1 cum )]

= 5.44 cum. i.e. 192.2 cu ft.

Note: The values i.e. directly added above is taken from “Calculating the quantity of materials in different grades of concrete“.

Now, we will sum up the total quantities of cement, sand, & aggregates required for the compound wall construction.

Note: The values i.e. mentioned below are taken from all above 8 parts of the series.

The total number of cement bags for compound wall.

= [for PCC + for masonry + for RCC + for coping]

= [17.16 + 4.501 + 52.23 + 4.632]

= 78.523 bags

The total volume of sand required in the compound works

= [for PCC + for masonry + for RCC + for coping ]

= [42.09 + 33.12 + 96.1 + 11.361]

= 182.671 cu ft.

The total volume of coarse aggregates required in the compound work.

= [for PCC + for RCC + for coping]

= [84.19 + 192.2 + 22.722]

= 299.11 cu ft.

The total weight of rebars required for the compound work.

= for footing + for plinth beam + for columns

= [56.55 kgs + 330.82 kgs. + 226.152 kgs.]

= 613.522 kgs.

OTHER POSTS:

-

Thumb Rules for Staircase Design Calculation | Concrete Calculation of Staircase

-

How to Calculate the Shuttering Quantity for Staircase

-

Thumb Rules for Staircase Design Calculation | Concrete Calculation of Staircase

-

Bar Bending Schedule of Staircase | Staircase Reinforcement Detail

Conclusion:

In conclusion, preparing a compound wall estimate with a bar bending schedule is an essential part of the construction process. It ensures that the right amount of material and resources are utilized, making the construction process more efficient and cost-effective. A bar bending schedule also helps in ensuring the strength and stability of the wall, making it a crucial aspect of any construction project.

2 Comments

Waah

Very useful information that is always provided here.