Bar Bending Schedule of Lintel Beam | Typical Beam | Detailed Beam

In this Article today we will talk about the Bar Bending Schedule of Lintel Beam | Blockwork Lintel | Concrete Lintel | Steel Estimation | Bar Bending Schedule Software | BBS of Lintel Beam | Bar Bending Schedule of Beam | Cutting Length of Steel Bar | Bar Bending Schedule Calculation Excel | Bar Bending Formula

Bar Bending Schedule of Beam

We know the importance of the Bar Bending Schedule and have already discussed it.

Here we are going to see the Bar Bending Schedu e for Beam. It’s not totaly different from slab calcu ation. Blockwork Lintel

Before starting the topic make sure that you have read the below topics Blockwork Lintel

- Why steel is used in Concrete? Concrete Lintel

- Bar Bending Shape Codes Blockwork Lintel

- Bar Bending Schedule Basic Formulas

- What is Development Length and Lap Length?

- Types of Stirrups in Reinforcement

Thumb Rules for Lintel Beam:

- The minimum bearing for lintels onto brickwork shall be 150 mm

- The minimum bearing for lintel onto Blockwork shall be 300 mm

- Lintel shall bear on whole blocks not cut Blocks

- Lintels are to be added in mortar similar to that used for laying the units.

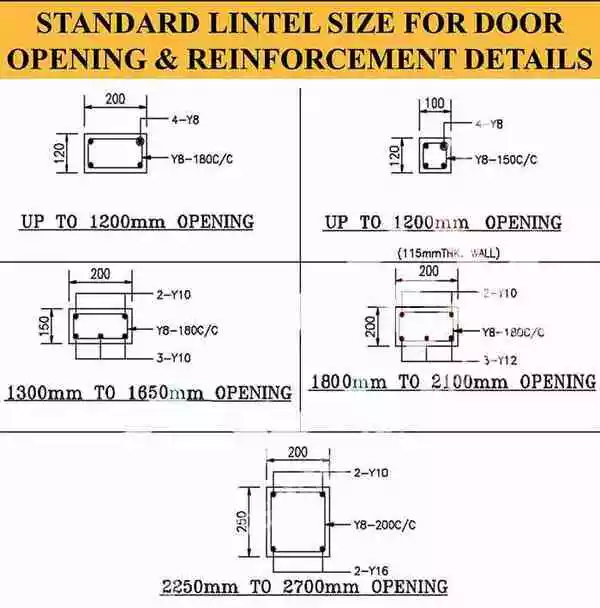

- The width of the lintel should be equal to the thickness of opening and depth in the range between 1/2 to 1/8 of the span. Concrete Lintel

We will discuss this scheduling topic as two parts, one for a Lintel Beam, second for a typical beam and third for detailed beam design specification.

Let’s start.

Bar Bending Schedule of a Lintel Beam:

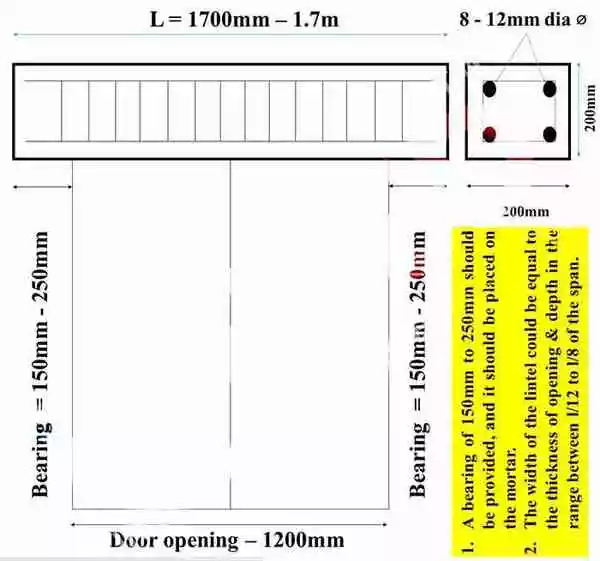

Given Data:

- Length of Lintel Beam = 1700 mm = 1.7 m

- Bearings = 150 mm Steel Estimation

- Breadth of Lintel Beam = 200 mm = 0.2 m

- Depth of Lintel Beam = 200 mm = 0.2 m

- Length of Door = 1200 mm = 1.2 m

- Clear Cover = 25mm = 0.025 m Steel Estimation

STEP-1: Calculate Length Of One Main Bar

Length of one bar = Length of door opening + (2 x bearing length) – clear cover for both sides Steel Estimation

Length of door = 1200mm – 1.2m

Bearing length = 150mm (150 mm to 200 mm bearing length should be provided and it should be placed on the motor.)

Clear cover = 25mm (we will take 25mm as clear cover)

Length of one bar = 1.2+ (2 x 0.150) – 0.025 =1.475m Steel Estimation

STEP-2: Calculate Total Length Of Main Bars

Before we calculate the total length of the main bars. We should know how many bars we are going to use in lintel reinforcement.

Below tips will help you to select proper how many bars we should use:

As we have a length of the lintel is more than 1.3m so we will have to choose 5nos of bars for the lintel reinforcement Bar Bending Schedule Software

So, Bar Bending Formula

We need 5 nos of 1.425m length of 10mm bars. In that case

Length of 5 bars = 1.425 x 5 = 7.125m Bar Bending Formula

STEP-3: Calculate Weight Of Steel For Main Bars

Weight of steel for 10 mm bar = D²L/162 = 10² x 7.125/162 = 4.398 kg.

STEP-4: Calculate Length Of One Stirrups

As we know size of bar is 200mm x 200mm

Cutting length of stirrups = (2x depth distance) +(2xWidth depth) + Hooks Length – Bend

Depth distance = depth – (2 x clear cover) – (dia of stirrups)

Depth distance = 200 -25 -25 – 8 = 142 mm

width distance = depth – (2 x clear cover) – (dia of stirrups)

width distance = 200 -25 -25 – 8 = 142 mm

Hooks length = 9d

Bend = 2d

We have 2 hooks and 5 bend

So,

Cutting length of stirrups = (2×142) + (2 x 142) + (2x9x8) –(5x2x8) = 632 mm = 0.632 m Bar Bending Schedule Calculation Excel

STEP-5: Calculate No Of Stirrups

No of stirrups = (Total length of lintel / distance between strriups) + 1

= (1.475/0.150) + 1 = 10.8 = 11nos

Total length of stirrups = 0.632 x 11nos = 6.952m Bar Bending Schedule Calculation Excel

STEP-6: Calculate Weight Of Steel For Stirrups

Weight of steel for stirrups = D²L/162 = 8² x 6.952/162 = 2.746 kg.

So we can order steel bar as,

7m (6.952) of 8mm bar

7.5m (7.125) of 10mm bar Cutting Length of Steel Bar

Bar Bending Schedule of a Typical Beam:

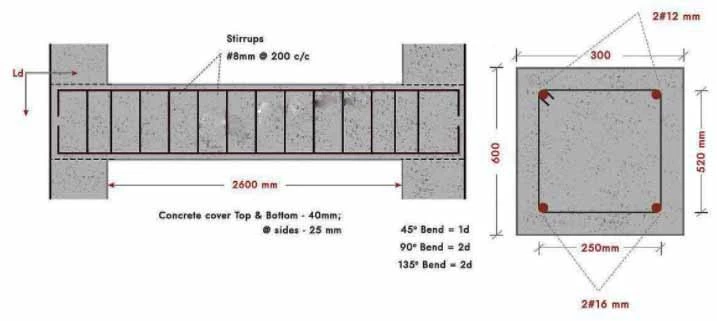

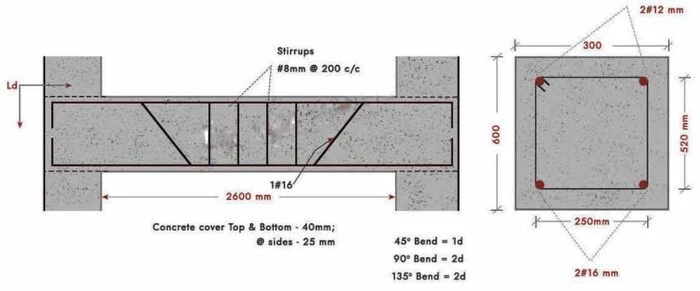

From the diagram, we can extract the be ow data

Given Data

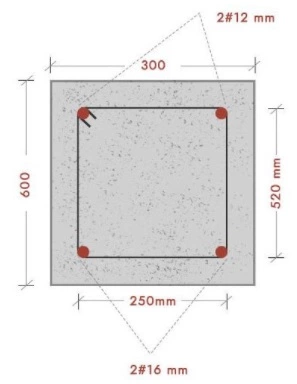

- Beam Size – 600 x 300 x 2600 mm

- Bottom Reinforcement 16mm of 2 numbers

- Top Reinforcement 12mm of 2 numbers

- Stirrups – 8mm of 200 c/c

- Concrete cover – 2 5 mm @ sides & 40mm @ top & bottom

- Development Length as 50d (assumption) Cutting Length of Steel Bar

Step 1- Find Cutting Length of Top & Bottom Bars

Cutting Length of Top Bar = Lclear + 2 x Deve opment Length = 2600 + (2x 50x 12) = 3800 mm

Cutting Length of Bottom Bar = Lclear + 2 x Development Length = 2600 + (2x50x16) = 4200 mm BBS of Lintel Beam

Step 2 – Find Number of Stirrups

Number of Stirr ups = Lclear / Spacing +1 = 2600/ 200 = 13 +1 = 14 Nos

Step 3 – Find Cutting Length of Stirrups

Cutting Length of Stirrups = Sum of total engths (excluding cover) – 3 nos of 90° bends – 2 nos of 135° bends + 2 nos of Hook Length

We have a detailed post about cutting Length of stirrups.

Assuming Length of one hook = 9d

Cutting Length of Stirrups = (520+250+520+ 250)-(3 x 2d)- (2 x 3d)+ 2x9d) = 1540-(3x2x8)-(2x3x8) + (2x9x8) = 1588 mm

Cutting Length of Stirrups = 1588 mm or 1.59 m BBS of Lintel Beam

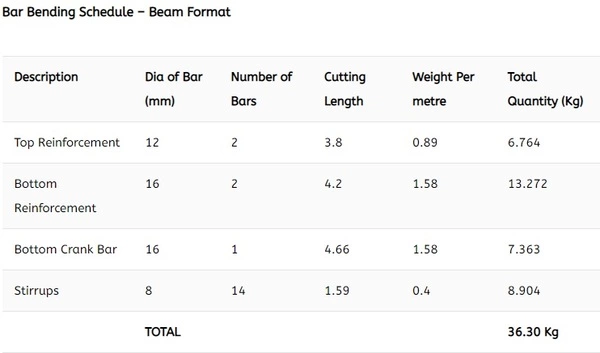

Step 4: Bar Bending Schedule – Typical Beam Format

Bar Bending Schedule for Detailed Beam

Sometimes beams will come up with an extra one crank bar at the centre as shown in the diagram below.

From the diagram, we can extract the be ow data

Given Data

- Beam Size – 600 x 300 x 2600 mm

- Bottom Reinforcement 16mm of 2 numbers

- Crank bar at bottom reinforcement 16mm of 1 number

- Top Reinforcement 12 mm of 2 numbers

- Stirrups – 8mm of 200 c/c

- Concrete cover – 25 mm @ sides & 40mm @ top & bottom

- Deve opment Length as 50d (assumption)

Step 1- Find Cutting Length of Top & Bottom Bars

Cutting Length of Top Bar = Lclear + 2 x Development Length = 2600 + (2x50x12) = 3800 mm

Cutting Length of Bottom Bar = Lclear + 2 x Development Length = 2600 + (2x50x16) = 4200 mm

Cutting Length of Bottom Crank Bar = Lclear + (2 x 0.42H) + (2 x 45° bend) + (2 x Deve opment Length)

Length of crank bar = 0.42 H

Where, H = Beam Depth – Concrete Cover – dia of bar = 600 – (2 x 40) – 16 = 504 mm

Cutting Length of Bottom Crank Bar = 2600 + (2 x0.42 x 504) + (2x1d) + (2 x 50d)

= 2600 + (2 x 0.42 x 504) + (2 x 1x 16) + (2 x 50 x 16) = 4655.36 mm or 4.66 m

Step 2 – Find Number of Stirrups

Number of Stirrups = Lclear / Spacing +1 = 2600/ 200 = 13 +1 = 14 Nos

Step 3 – Find Cutting Length of Stirrups

Cutting Length of Stirrups = Sum of total Lengths (excluding cover) – 3 nos of 90° bend – 2 nos of 135° bend + 2 nos of Hook Length

Assuming Length of one hook = 9d

= (520+250+ 520+250) – (3 x 2d) – (2 x 3d) + (2x9d) = 1540 – (3x2x8) – (2x3x8) + (2x9x8)

= 1588 mm

Cutting Length of Stirrups = 1588 mm or 1.59 m

Step 4: Bar Bending Schedule – Detailed Beam Format:

OTHER POSTS:

-

How to Calculate the Cutting Length of Spiral Bar or Helix Bar | BBS

-

How to Calculate Cutting Length of Bent Up Bar in Slab

-

How to Calculate Unit Weight of Steel Bars | Steel Weight Formula

-

How To Find Out The Cutting Length Of Main Bars & Circular Rings

-

Bar Bending Schedule (BBS) | BBS Step by Step Preparation | Excel Sheet

-

Bar Bending Schedule Basic Formulas | BBS Formula | What is BBS

Conclusion:

Full article on Bar Bending Schedule of Lintel Beam | Blockwork Lintel | Concrete Lintel | Steel Estimation | Bar Bending Schedule Software | BBS of Lintel Beam | Bar Bending Schedule of Beam | Cutting Length of Steel Bar | Bar Bending Schedule Calculation Excel | Bar Bending Formula. Thank you for the full reading of this article in “The Civil Engineering” platform in English. If you find this post helpful, then help others by sharing it on social media. If any formula of BBS is missing from this article please tell me in comments.

8 Comments

Very. easy steps and also quick -keep it up – I Recommend to all my friends

thanks

Sir your contact number what up no please

you can message here, Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar

Very easy steps and also quick -keep it up – I Recommend to all my friends

Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar

Good evening sir 3000 squire feat ka Excel per site cleaning se Bil off quantity yani aggregate sandbric plaster painting and send brick Steel labour cement arthat use quantity rupees value

Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar