Useful Guidelines for Design of RCC Slab | Requirements for RCC Slab Design | Basic Rules for Design of RCC Slab

In this Article today we will talk about the Useful Guidelines for Design of RCC Slab | Requirements for RCC Slab Design | Basic Rules for Design of RCC Slab | Tips for Design of RCC Slab | Slab Design Calculations | RCC Slab Design Formula

Reinforced Concrete Slab:

A Reinforced Concrete Slab is the one of the most important component in a building. It is a structural element of modern buildings. Slabs are supported on Columns and Beams.

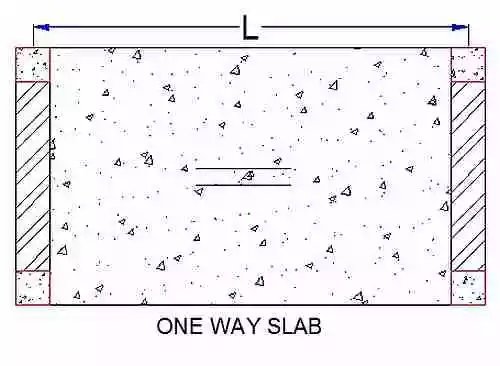

One Way Slab:

One way slab is a slab which is supported by beams on the two opposite sides to carry the load along one direction. The ratio of longer span (l) to shorter span (b) is equal or greater than 2, considered as One way slab because this slab will bend in one direction i.e in the direction along its shorter span. Requirements for RCC Slab Design

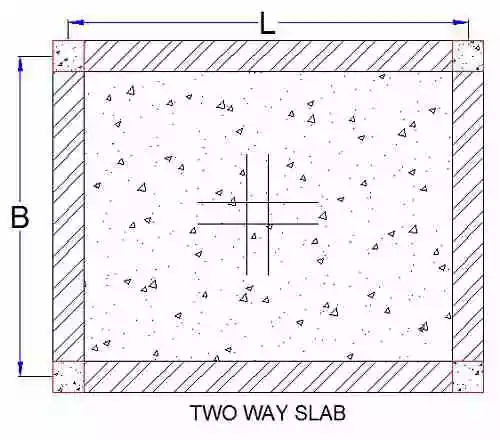

Two Way Slab:

Two way slab is a slab supported by beams on all the four sides and the loads are carried by the supports along with both directions, it is known as two way slab. In two way slab, the ratio of longer span (l) to shorter span (b) is less than 2.

The remaining 50% should extend to within 0.1Lx or Ly at the support as appropriate. You can use a free app to design simply supported RCC Slab panel.

RCC Slab Design depends on the on the dimensions of the slab after which the slab is termed as a one-way slab or a two-way slab. Slab Design Calculations

In the design of RCC structures, Column Design and Beam Design are to be done before we start with RCC Slab Design. Tips for Design of RCC Slab

Basic Rules for Design of RCC Slab:

Effective Span of Slab:

Effective span of slab shall be lesser of the two

- L = clear span + d (effective depth)

- L = Center to center distance between the support

For Simply Supported Slab

- Minimum of clear span plus effective depth of slab

- Center to centre distance between the supports

For Cantilever Slab

- Length up to face of support + Half the effective depth.

- Where it forms end of a continuous slab, the length of centre of support shall be taken. Slab Design Calculations

Depth or Thickness of Slab:

The depth of slab depends on bending moment and deflection criterion. the trail depth can be obtained using:

- Effective depth d= Span /((L/d)Basic x modification factor)

- For obtaining modification factor, the percentage of steel for slab can be assumed from 0.2 to 0.5%.

- The effective depth d of two way slabs can also be assumed using cl.24.1,IS 456 provided short span is <3.5m and loading class is <3.5KN/m2

| Type of support | Fe-250 | Fe-415 |

| Simply supported | L/35 | L/28 |

| Continuous support | L/40 | L/32 |

Or, the following thumb rules can be used:

- One way slab d = (L/22) to (L/28).

- Two way simply supported slab d = (L/20) to (L/30)

- Two way restrained slab d = (L/30) to (L/32)

Load on Slab:

The load on slab comprises of Dead load, floor finish and live load. The loads are calculated per unit area (load/m2).

Dead load = D x 25 KN/m2 ( Where D is thickness of slab in m) Floor finish (Assumed as) = 1 to 2 KN/m2

Live load (Assumed as) = 3 to 5 KN/m2 (depending on the occupancy of the building)

Limiting Stiffness:

For span up to 10m, the Basic values of span to depth ration are given below

- Cantilevers-7

- Simply supported- 20

- Continuous- 26 Slab Design Calculations

Minimum Reinforcement for Concrete Slab Design:

The reinforcement in either direction in slab shall not be less than

- 0.15% of the total cross sectional area for Fe-250 steel

- 0.12% of the total cross-sectional area for Fe-415 & Fe-500 steel.

Maximum Diameter of Bars:

The maximum diameter of bar in slab, shall not exceed D/8, where D is the total thickness of slab. RCC Slab Design Formula

Spacing of Main Reinforcement:

The maximum spacing of bars shall not exceed

- Main Steel – 3d or 300 mm whichever is smaller

Distribution Reinforcement for Concrete Slab Design:

The area of distribution reinforcement shall not be less than 0.15%of gross cross-sectional area if plain bars are used and 0.12% of high yield strength deformed bars are used.

- Distribution steel –5d or 450 mm whichever is smaller Where, ‘d’ is the effective depth of slab. Note: The minimum clear spacing of bars is not kept less than 75 mm (Preferably 100 mm) though code do not recommend any value

Nominal Cover to Reinforcement:

For Mild exposure – 20 mm For Moderate exposure – 30 mm However, if the diameter of bar do not exceed 12 mm, or cover may be reduced by 5 mm.

Thus for main reinforcement up to 12 mm diameter bar and for mild exposure, the nominal cover is 15 mm. RCC Slab Design Formula

FAQ’s

What is Reinforced Cement Concrete Slab ?

- RCC Slabs whose thickness ranges from 10 to 50 centimeters are most often used for the construction of floors and ceilings.

- Thin concrete slabs are also used for exterior paving purpose.

- In many domestic and industrial buildings a thick concrete slab, supported on foundations or directly on the sub soil, is used to construct the ground floor of a building.

- In high rises buildings and skyscrapers, thinner, pre-cast concrete slabs are slung between the steel frames to form the floors and ceilings on each level.

- While making structural drawings of the reinforced concrete slab, the slabs are abbreviated to “r.c.slab” or simply “r.c.”.

What are the Design of various types of Slabs and their Reinforcement ?

For a suspended slab, there are a number of designs to improve the strength-to-weight ratio. In all cases the top surface remains flat, and the underside is modulated:

- Corrugated, usually where the concrete is poured into a corrugated steel tray. This improves strength and prevents the slab bending under its own weight. The corrugations run across the short dimension, from side to side.

- A ribbed slab, giving considerable extra strength on one direction.

- A waffle slab, giving added strength in both directions.

Reinforcement design

- A one way slab has structural strength in shortest direction.

- A two way slab has structural strength in two directions.

These slabs could be cantilevered or Simply Supported Slabs.

What is the Construction Procedure of Slabs ?

- A concrete slab can be cast in two ways: It could either be prefabricated or cast in situ.

- Prefabricated concrete slabs are cast in a factory and then transported to the site ready to be lowered into place between steel or concrete beams.

- They may be pre-stressed (in the factory), post-stressed (on site), or unstressed. Care should be taken to see that the supporting structure is built to the correct dimensions to avoid trouble with the fitting of slabs over the supporting structure.

- In situ concrete slabs are built on the building site using formwork. Formwork is a box-like setup in which concrete is poured for the construction of slabs.

- For reinforced concrete slabs, reinforcing steel bars are placed within the formwork and then the concrete is poured.

- Plastic tipped metal, or plastic bar chairs are used to hold the reinforcing steel bars away from the bottom and sides of the form-work, so that when the concrete sets it completely envelops the reinforcement.

- Formwork differs with the kind of slab. For a ground slab, the form-work may consist only of sidewalls pushed into the ground whereas for a suspended slab, the form-work is shaped like a tray, often supported by a temporary scaffold until the concrete sets.

OTHER POSTS:

-

How to Calculate Shuttering Area of Column, Beam and Slab

-

How to Load Calculation on Column, Beam, Wall & Slab

-

Method Statement for Pouring Concrete on Slab on Grade (S.O.G)

-

How to Calculate Bar Bending Schedule of Slab in Excel | BBS of Slab

-

Useful Tips for Design of RCC Members | Beam, Column, Slab, Footing

Conclusion:

Full article on Useful Guidelines for Design of RCC Slab | Requirements for RCC Slab Design | Basic Rules for Design of RCC Slab | Tips for Design of RCC Slab | Slab Design Calculations | RCC Slab Design Formula. Thank you for the full reading of this article in “The Civil Engineering” platform in English. If you find this post helpful, then help others by sharing it on social media. If any formula of BBS is missing from this article please tell me in comments.

4 Comments

Good for engineering works and design

Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar

informative

Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar