Asphalt Concrete Paving Receiving, Placement and Testing Inspection | Asphalt Wearing and Binder Course | Asphalt Concrete Placement and Compaction | Asphalt Concrete Testing:

In this article we will discuss about Asphalt Concrete Paving | Asphalt Concrete Placement | Asphalt Wearing and Binder Course | Asphalt Concrete Compaction | Asphalt Concrete Testing.

The components of asphalt concrete include asphalt aggregate and asphalt binder. Mineral filler is sometimes added to hot mix asphalt concrete.

Asphalt Concrete Receiving Inspection | Wearing and Binder Course:

- The hot mix asphalt concrete material shall not be accepted unless it is covered with tarpaulins until unloaded.

- The hot mix asphalt using the conventional bitumen, shall have a temperature between 139°C and 163°C at the time of delivery.

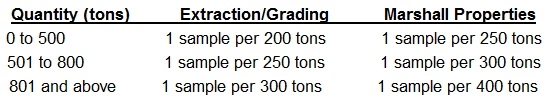

- Uncompacted asphalt concrete samples shall be taken daily for extraction, gradation and Marshall properties at the following rates of production:

Asphalt Concrete Placement and Compaction Inspection | Wearing and Binder Course:

- At the time of spreading and compaction, the conventional hot mix asphalt concrete material shall be at least 139°C.

- Polymer modified asphalt mix shall be placed and compacted at a temperature determined from the viscosity-temperature relationship which is estimated to be in the range of 155°C to 165°C.

- The hot mix asphalt concrete shall be placed only when the atmospheric temperature is 4°C or above, and when the weather is not foggy or rainy and when the existing surface is free from moisture.

- Any existing pavement shall be saw-cut, primed and tacked prior to placing new hot mix asphalt.

- Steel skid equipment shall not be used for placing hot mix asphalt until after the first layer is placed.

- Bituminous mixture shall be placed so that after rolling, the nominal thickness of the compacted bituminous material shall not be more than 80mm per layer.

- The Client Representative may give approval to greater than 80 mm thick layers, if the contractor can prove that he can achieve the requirements by field trials, using the compacting equipment and rolling patterns that he intends to use. Note: Approval of thicker lift by the Client representative does not relieve the Contractor’s responsibility to meet the project requirements.

- Trials strips shall be performed at the actual project site, and shall be removed at the Contractor expense, if the requirements were not achieved.

- All compaction shall be completed before the temperature of the mix falls below 90°C.

- The finished surface shall be free of open-textured areas of asphalt.

- In no case shall thin layers of fine materials be added to the top of the wearing course in order to achieve the required thickness or specified tolerances.

- Areas of asphalt which fail to meet the required tolerances and/or compaction shall be removed by saw cutting to the full depth of the wearing course and base course, forming parallel and perpendicular lines extending to the architectural features where practical.

- Areas cut out for repair shall receive additional prime coat prior to placing asphalt materials.

- Newly paved areas shall be protected from traffic by barricades or other suitable methods that meet Saudi Arabian Government requirements.

- Asphalt pavement shall not be in contact with pipelines that are catholically protected.

OTHER POSTS:

-

Method Statement for Asphalt Paving Works | Asphalt Concrete

-

Asphalt Concrete Pavement Placement Requirements

-

Asphalt Concrete Pavement Material Specifications

Asphalt Concrete Laboratory Testing | Wearing and Binder Course:

- All quality tests and sampling on raw materials shall be performed by a Saudi Aramco approved independent laboratory in the presence of Contractor and Client Representatives.

- Third Party Agency’s Quality Personnel assigned to the Work must be technically competent to perform their duties and shall have a recommendation for approval from Saudi Aramco to perform applicable Tests.

- Tests performed in accordance to applicable Standards in the presence of Contractor and Client Representatives.

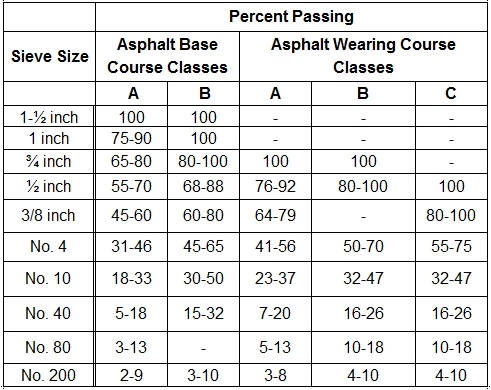

- Gradation when tested according to ASTM C117 and ASTM C136 for combined mineral aggregates shall conform to the following:

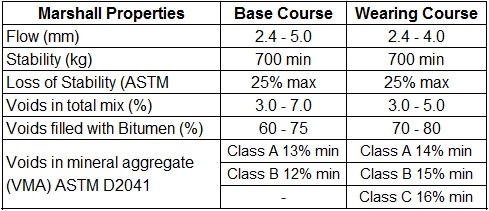

- Bituminous Mixtures shall conform to the following requirements:

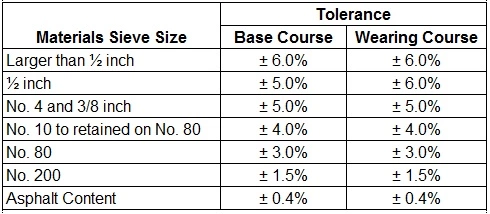

- Final asphalt mix when compared to the Job Mix Formula shall be within the following limits:

- The compaction requirements shall be equal to or greater than 96% of the Marshall density per ASTM D1559 using material sampled at the road site.

Conclusion:

Full article on Asphalt Concrete Paving | Asphalt Concrete Placement | Asphalt Wearing and Binder Course | Asphalt Concrete Compaction | Asphalt Concrete Testing. Thank you for the full reading of this article in “The Civil Engineering” platform in English. If you find this post helpful, then help others by sharing it on social media. If you have any question regarding article please tell me in comments.