Concrete Slump Test for Workability | Slump Test of Concrete

In this Article today we will talk about the Concrete Slump Test for Workability | Slump Test of Concrete Values | Types of Concrete Slump | Slump Cone Test Formula | Slump Test Procedure pdf | Concrete Slump Range | slum test | slumb test | slupm test | slump.cone test | slumps test

How to Determine Concrete Slump Test:

ASTM Designation

ASTM C143—Slump of Portland Cement Concrete

Purpose of Concrete Slump Test:

To determine the slump of freshly mixed Portland cement concrete, both in the laboratory and in the field.

Principle of Slump Test

The slump test result is a measure of the behavior of a compacted inverted cone of concrete under the action of gravity. It measures the consistency or the wetness of concrete which then gives an idea about the workability condition of concrete mix.

Significance and Use

This method measures the consistency of freshly mixed Portland concrete cement (PCC). To some extent, this test indicates how easily concrete can be placed and compacted, or the workability of concrete. This test is used both in the laboratory and in the field for quality control. Types of Concrete Slump slum test

Apparatus:

The items required for a slump test: slum test

- Slump Cone Mold—The mold is 12-in. in height and known as an Abrams cone.

- Scoop—To place the concrete sample into the mouth of the cone. slum test

- Steel Tamping Rod—This is a 5/8-in. diameter, smooth-surfaced, 24-in. long rod with hemispherical (rounded) tips. slum test

- Baseplate—Or some similar non-absorbent surface.

- Tape Measure—Or a ruler to record the test result. slum test

- Sponge or Brush & Water—To dampen the cone and base before the test.

Slump Test Procedure pdf

1. Mix concrete either manually or with a mechanical mixer (Figure A.27). If a large quantity of mixed concrete exits, obtain a representative sample.

2. Dampen the mold and place it, with its larger base at the bottom, on a flat, moist, nonabsorbent rigid surface. Types of Concrete Slump

3. Hold the mold firmly in place by standing on the two foot pieces.

4. Immediately fill the mold in three layers, each approximately one-third of the volume of the mold. Note that one-third of the volume is equivalent to a depth of 67 mm (2-5/8 in.), whereas two-thirds of the volume is equivalent to 155 mm (6-1/8 in.).

5. Rod each layer 25 strokes, using the tamping rod (Figure A.28). Uniformly distribute the strokes over the cross section of each layer. Rod the second and top layers each throughout its depth so that the strokes penetrate the underlying layer. In filling and rodding the top layer, heap the concrete above the mold before rodding is started. If the rodding operation results in subsidence of concrete below the top edge of the mold, add additional concrete to keep an excess of concrete above the top of the mold at all times.

FIGURE A.28 | Rodding fresh concrete in the slump cone with a tamping rod.

6. After the top layer has been rodded, strike off the surface of concrete by means of a screening and rolling motion of the tamping rod.

7. Remove the mold immediately from the concrete by raising it up carefully without lateral or torsional motion. The slump test must be completed within 2.5 minutes after taking the sample.

8. Measure the slump by determining the vertical difference between the top of the mold and the displaced original center of the top of the specimen, as shown in Figure A.29. If two consecutive tests on a sample of concrete show a falling away or a shearing off of a portion of concrete from the mass of the specimen, the concrete probably lacks the necessary plasticity and cohesiveness for the slump test to be applicable and the test results will not be valid.

Precautions in Slump Test

In order to reduce the influence on slump of the variation in the surface friction, the inside of the mould and its base should be moistened at the beginning of every test, and prior to lifting of the mould the area immediately around the base of the cone should be cleaned from concrete which may have dropped accidentally.

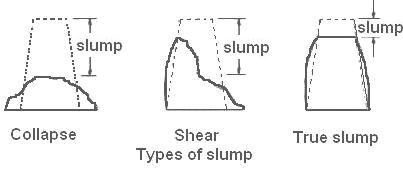

Types Of Concrete Slump

The slumped concrete takes various shapes, and according to the profile of slumped concrete, the slump is termed as;

- Collapse Slump

- Shear Slump

- True Slump

Collapse Slump

In a collapse slump the concrete collapses completely. A collapse slump will generally mean that the mix is too wet or that it is a high workability mix, for which slump test is not appropriate. It means the water-cement ratio is too high, i.e. concrete mix is too wet or it is a high workability mix, for which a slump test is not appropriate.

Shear Slump

In a shear slump the top portion of the concrete shears off and slips sideways. OR If one-half of the cone slides down an inclined plane, the slump is said to be a shear slump. The shear slump indicates that the result is incomplete, and concrete needs to be retested for valid results.

- If a shear or collapse slump is achieved, a fresh sample should be taken and the test is repeated.

- If the shear slump persists, as may the case with harsh mixes, this is an indication of lack of cohesion of the mix.

True Slump

In a true slump the concrete simply subsides, keeping more or less to shape

- This is the only slump which is used in various tests.

- Mixes of stiff consistence have a Zero slump, so that in the rather dry range no variation can be detected between mixes of different workability.

However, in a lean mix with a tendency to harshness, a true slump can easily change to the shear slump type or even to collapse, and widely different values of slump can be obtained in different samples from the same mix; thus, the slump test is unreliable for lean mixes.

Applications of Slump Test

- The slump test is used to ensure uniformity for different batches of similar concrete under field conditions and to ascertain the effects of plasticizers on their introduction.

- This test is very useful on site as a check on the day-to-day or hour- to-hour variation in the materials being fed into the mixer. An increase in slump may mean, for instance, that the moisture content of aggregate has unexpectedly increases.

- Other cause would be a change in the grading of the aggregate, such as a deficiency of sand.

- Too high or too low a slump gives immediate warning and enables the mixer operator to remedy the situation.

- This application of slump test as well as its simplicity, is responsible for its widespread use. Slump Cone Test Formula

Concrete Slump Range

|

Degree of workability |

Slump |

Compacting Factor |

Use for which concrete is suitable |

|

|

mm |

in |

|||

|

Very low |

0-25 |

0-1 |

0.78 |

Very dry mixes; used in road making. Roads vibrated by power operated machines. |

|

Low |

25-50 |

1-2 |

0.85 |

Low workability mixes; used for foundations with light reinforcement. Roads vibrated by hand operated Machines. |

|

Medium |

50-100 |

2-4 |

0.92 |

Medium workability mixes; manually compacted flat slabs using crushed aggregates. Normal reinforced concrete manually compacted and heavily reinforced sections with vibrations. |

|

High |

100-175 |

4-7 |

0.95 |

High workability concrete; for sections with congested reinforcement. Not normally suitable for vibration |

Table : Workability, Slump and Compacting Factor of concrete with 19 or 38 mm (3/4 or 11/2 in) maximum size of aggregate. Slump Test Procedure pdf

Slump Test Standards

The concrete slump test is referred to in several testing and building code, with minor differences in the details of performing the test.

United States

In the United States, engineers use the ASTM standards and AASHTO specifications when referring to the concrete slump test. The American standards explicitly state that the slump cone should have a height of 12-in, a bottom diameter of 8-in and an upper diameter of 4-in.

The ASTM standards also state in the procedure that when the cone is removed, it should be lifted up vertically, without any rotational movement at all. The concrete slump test is known as “Standard Test Method for Slump of Hydraulic-Cement Concrete” and carries the code (ASTM C 143) or (AASHTO T 119). Slump Test Procedure pdf

United Kingdom & Europe

In the United Kingdom, the Standards specify a slump cone height of 300-mm, a bottom diameter of 200-mm and a top diameter of 100-mm. The British Standards do not explicitly specify that the cone should only be lifted vertically. The slump test in the British standards was first (BS 1881-102) and is now replaced by the European Standard (BS EN 12350-2).

Indian Standard Slump Test

- Indian standard: IS 1199 – 1959

FAQs

What is the ideal value of slump?

In case of a dry sample, slump will be in the range of 25-50 mm that is 1-2 inches. But in case of a wet concrete, the slump may vary from 150-175 mm or say 6-7 inches. So the value of slump is specifically mentioned along the mix design and thus it should be checked as per your location. slumps test

Factors affecting concrete workability are properties of concrete ingredients – aggregates etc. Also temperature has its effect on slump value. So all these parameters should be kept in mind when deciding the ideal slump slumps test

How does a super plasticizer effect the slump of concrete?

Value of Slump can be increased by the addition of chemical admixtures like mid-range or high-range water reducing agents (super-plasticizers) without changing the water/cement ratio. slumps test

How much time one should take to raise the cone?

Once the cone is filled and topped off [ excessive concrete from top is cleared ] raise the cone within 5-10 seconds. slumps test

What are the dimensions of the cone used in Slump Test?

The dimensions are: Top Diameter – 10cm Bottom Diameter – 20cm Height – 30cm slumps test

OTHER POSTS:

-

Compressive Strength Test of Concrete | Cube Test

-

Top 100 Interview Questions for Civil Engineer or QC Civil Inspector – Part1

-

Top 100 Interview Questions for Civil Engineer or QC Civil Inspector – Part2

-

Thumb Rules Formula for Civil Engineers & Quantity Surveyors

-

Excavation and Backfill Specifications | Earthwork Inspection Requirement

-

Important Core Knowledge for QA/QC Civil Engineers or Inspectors

Conclusion:

Full article on Concrete Slump Test for Workability | Slump Test of Concrete Values | Types of Concrete Slump | Slump Cone Test Formula | Slump Test Procedure pdf | Concrete Slump Range. Thank you for the full reading of this article in “The Civil Engineering” platform in English. If you find this post helpful, then help others by sharing it on social media. If any formula of BBS is missing from this article please tell me in comments. slumps test