Reinforcement Detailing of RCC Members | RCC Beam | RCC Column | RCC Staircase | RCC Footing | RCC Foundation | Development Length of Bars

In this Article today we will talk about the Reinforcement Detailing of RCC Members | RCC Beam | RCC Column | RCC Footing | RCC Staircase | Development Length of Bars | RCC Foundation.

Introduction:

Reinforcement detailing plays an important role in construction to resist the collapse of buildings from defective connection or detailing. Detailing can be done for the following Reinforced Cement Concrete (RCC) members:

- Slabs with or without openings (rectangular, circular, non-rectangular pyramid slab, triangular slab etc.)

- Beams with or without openings (shallow and deep beams)

- Columns with different shapes, such as; rectangular, L, T, circular, octagonal, cross etc.

- Foundations

- Gravity loads and lateral loads (particularly for the seismic forces).

- The rehabilitation and strengthening of damaged structures.

Do’s for detailing:

- Create perfect drawings and if possible label each bar and demonstrate its shape for transparency.

- Create a bar bending schedule when required.

- Specify perfect clear cover, nominal cover or effective cover to reinforcement.

- Determine detailed locations of openings or holes and provide sufficient details for reinforcements around the openings.

- The grade of steel should be mentioned in the drawing.

- Deformed bars should not contain hooks at their ends.

- Show enlarged details at corners, junctions of walls, beams and column joints.

- Congestion of bars should not occur at points where members overlap.

- For bundled bars, lapped splice of bundled bars should be created by splicing one bar at a time; such separate splices inside the bundle should be staggered.

- Ensure that hooked and bent up bars are arranged and contain sufficient concrete protection. RCC Beam

- Specify all extension, construction and contraction joints on plan and provide details for such joints. RCC Column

- The position of construction joints should remain at the point of minimum shear approximately at mid or adjacent to the mid points. It should be developed vertically and not in a sloped manner.

OTHER POSTS:

-

Basic Components of Road Structure and Method of Construction

-

Fill/Backfill Compaction Requirements for Sub Base, Base Course, Asphalt

-

What Is Tie Beam | Tie Beam Details | Advantages of Using Tie Beam

Do’s for Beam and Slab reinforcement detailing:

- When splices are arranged in bars, they should remain out of the sections of maximum stresses as far as possible and should be staggered.

- When the depth of beams surpass 750 mm in case of beams devoid of torsion and 450 mm with torsion provide face reinforcement according to IS456-2000.

- Deflection in slabs/beams is minimized with the compression reinforcement.

- Only closed stirrups are recommended for transverse reinforcement. For members susceptible to torsion and for members susceptible to reversal of stresses similar to seismic forces. RCC Footing

- To adapt bottom bars, secondary beams should be created shallower than primary beams, at least by 50 mm.

Do’s for column reinforcement detailing:

- A reinforced column should contain minimum six bars of longitudinal reinforcement to be used in transverse helical reinforcement for circular sections.

- At least four bars one at each corner should be provided in the case of rectangular sections.

- Retain exterior dimensions of columns fixed so far as possible to use the forms again.

- 2 grades of vertical bars should not be used in similar component.

Do not’s General:

- Reinforcement should not extend over an expansion joint and the break among the sections should be finished.

- Flexural reinforcement should not preferably be discontinued in a tension zone.

- Bars greater than 36 mm dia should not be bundled.

- Lap splices should not be utilised for bars greater than 36 mm dia. except where welded.

- When dowels are used, their diameter should not go beyond the diameter of the column bars in excess of 3 mm.

- When bent up bars are used, their participation towards shear resistance should not surpass 50% of the total shear to be countered. Single bent up bars alias cranked should not be used in earthquake resistance structures.

Reinforcement Detailing of RCC Members | Dos and Don’ts:

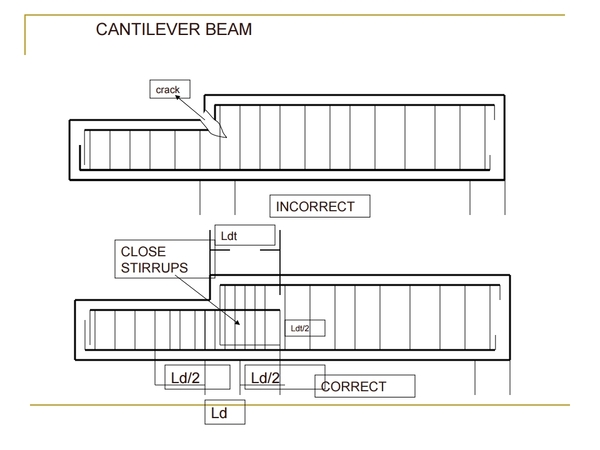

Cantilever Beam:

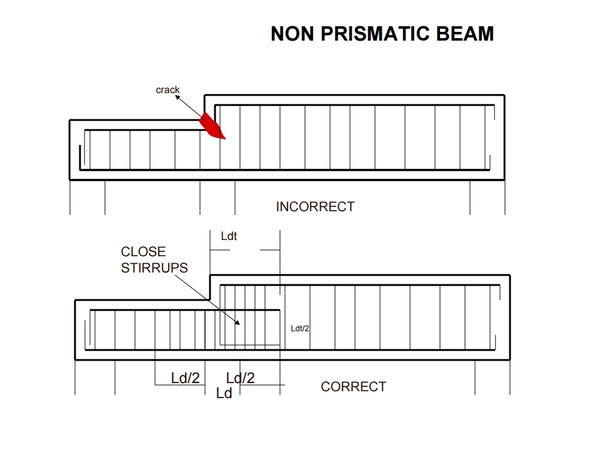

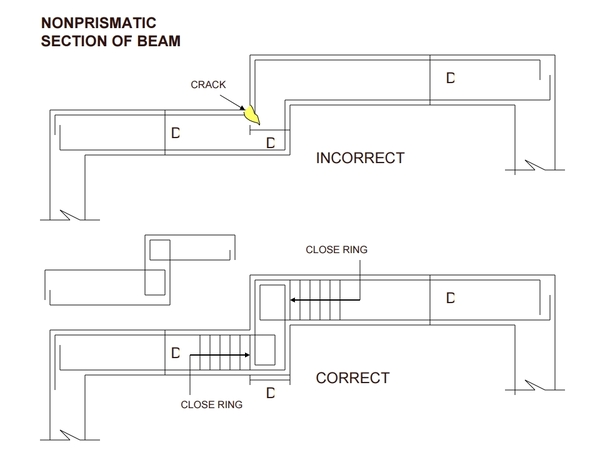

Non-Prismatic Beam:

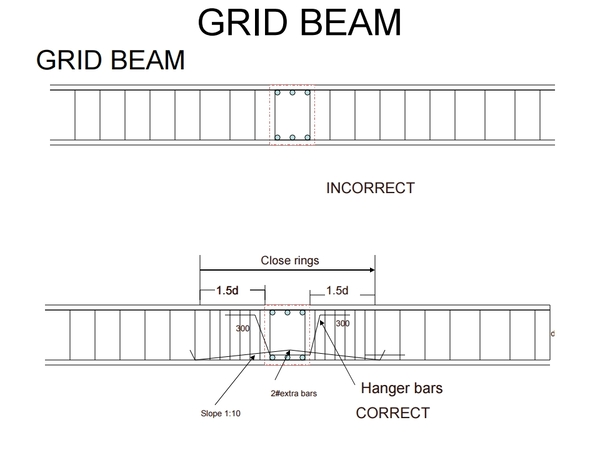

Grid Beam:

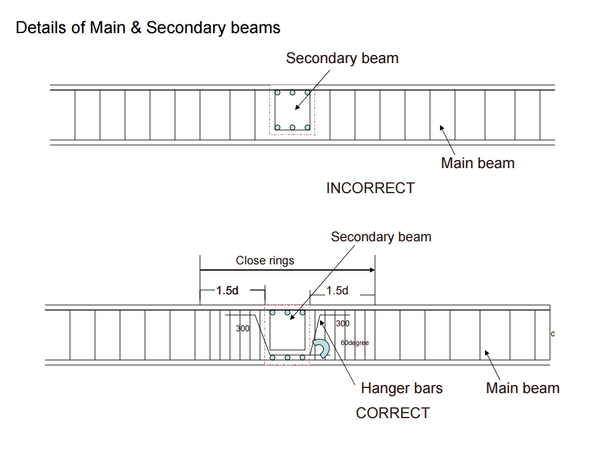

Main and Secondary Beam:

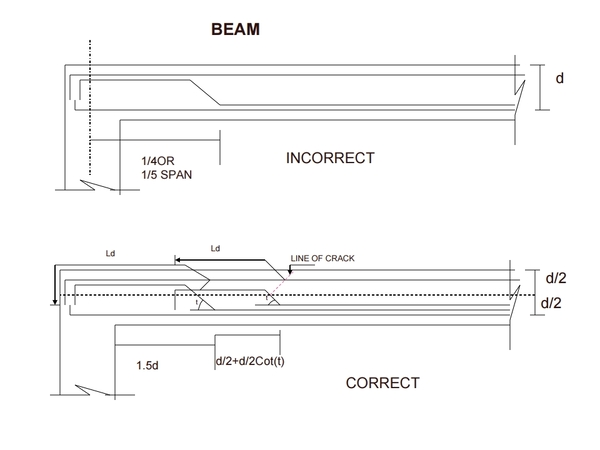

Simple Beam:

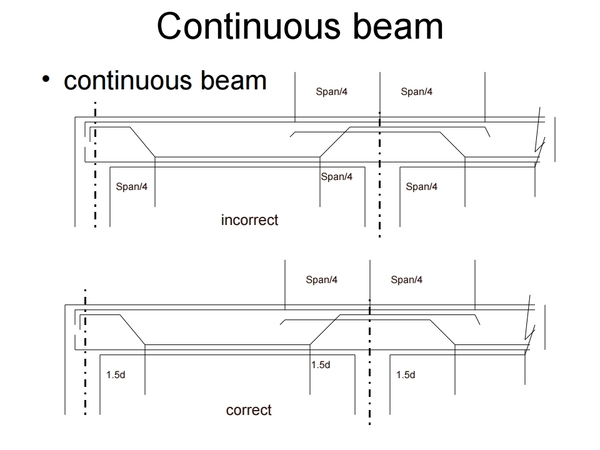

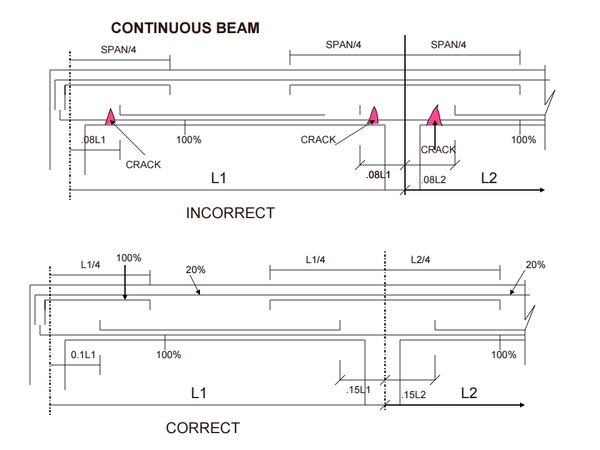

Continuous Beam Case 1:

Continuous Beam Case 2:

Non-Prismatic Section of Beam:

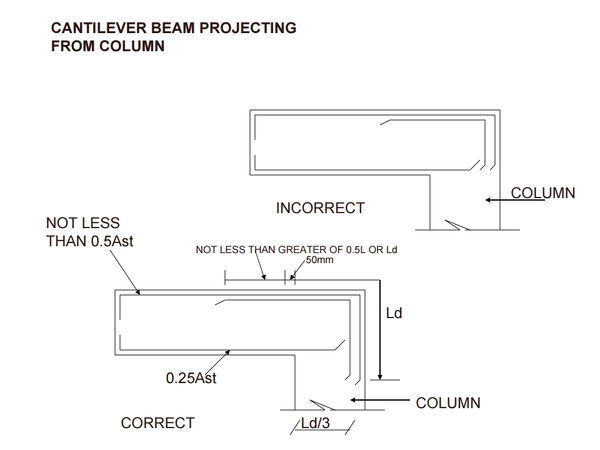

Cantilever Beam Projecting from Column:

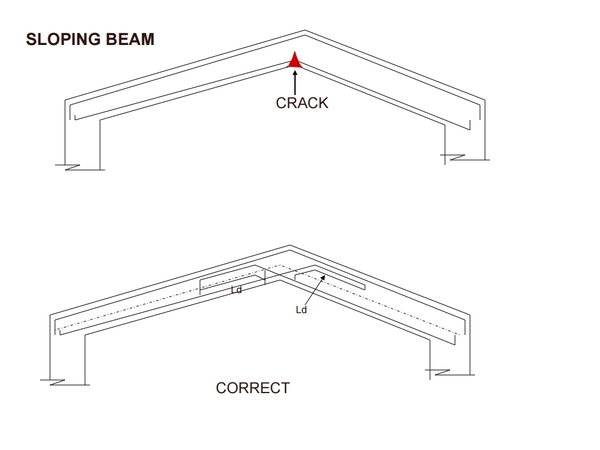

Sloping Beam:

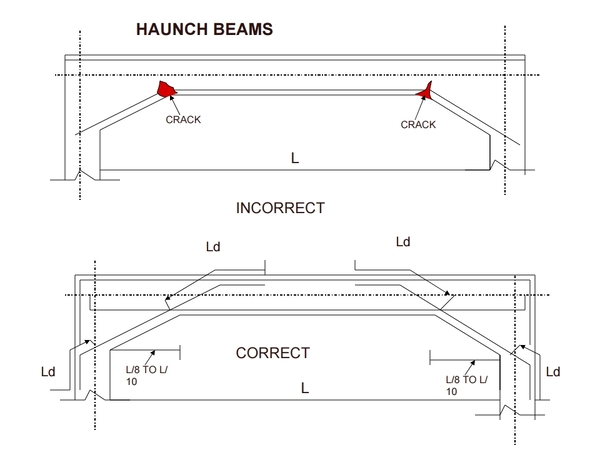

Haunch Beam:

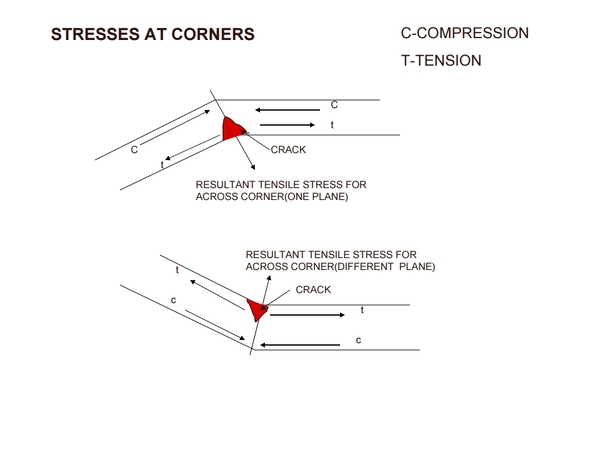

Stresses at Corners:

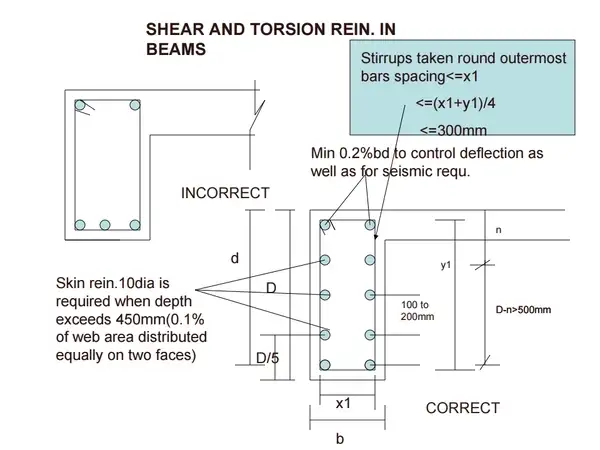

Shear and Torsion Reinforcement in Beam:

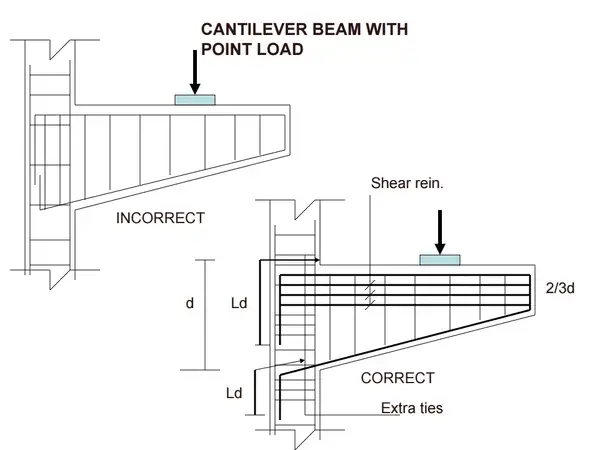

Cantilever Beam with Point Load:

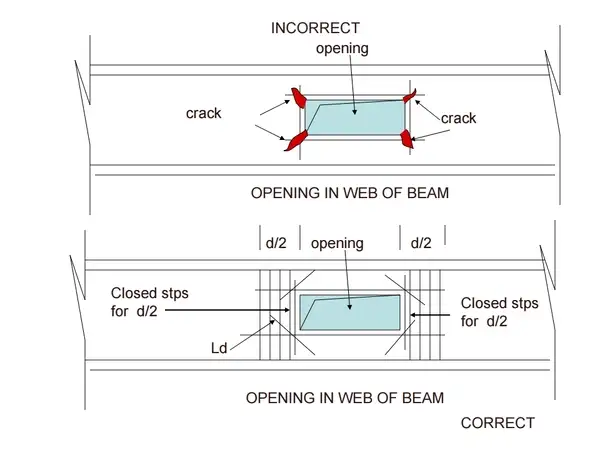

Opening in Web of Beam:

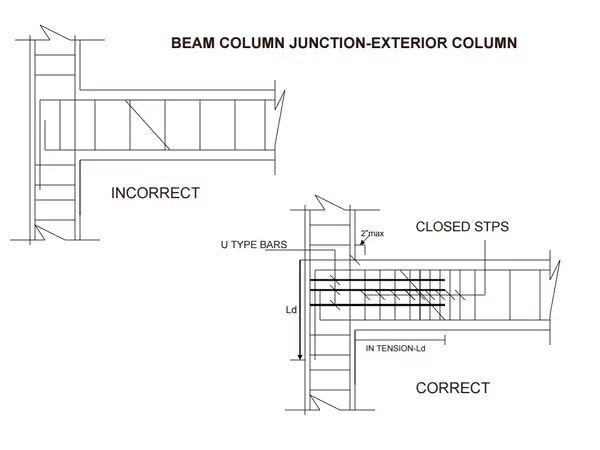

Beam Column Junction Exterior Column:

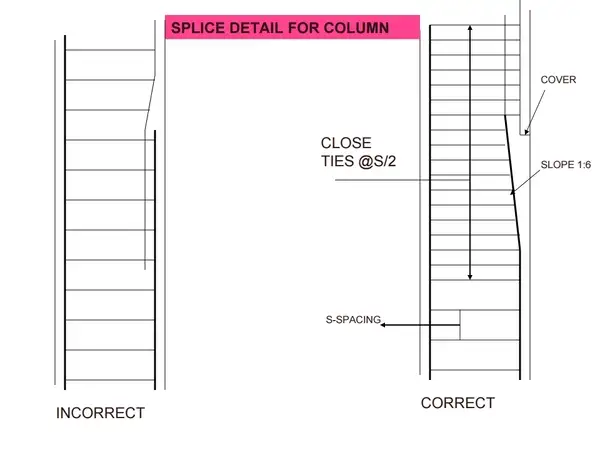

Splice Detail for Column:

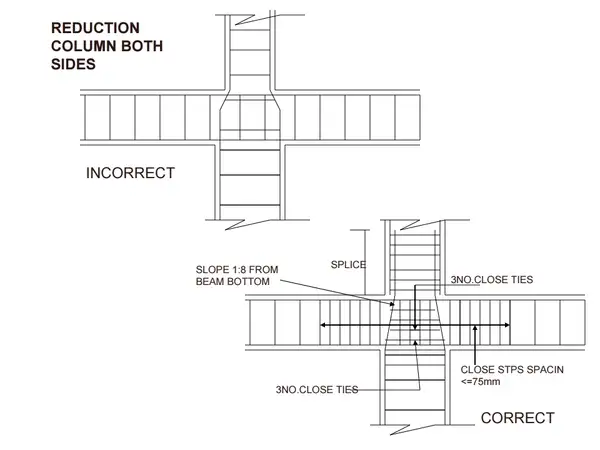

Reduction Column Both Sides:

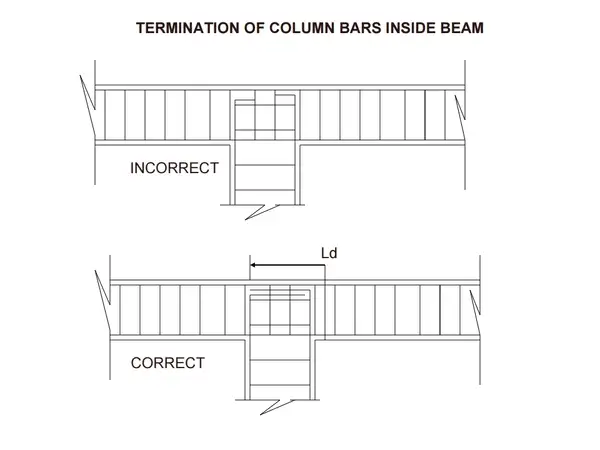

Termination of Column Bars inside Beam:

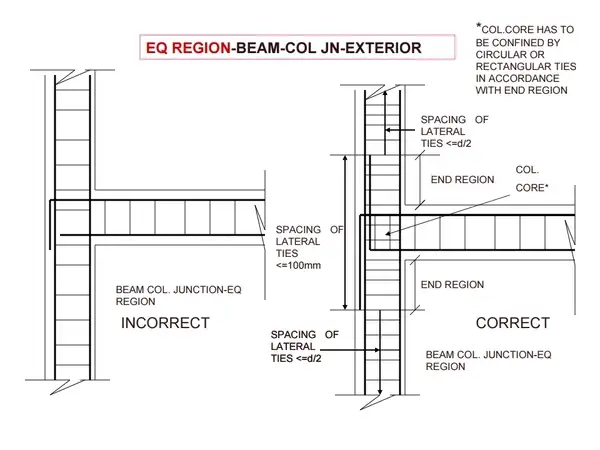

Eq Region Beam Colum Junction Exterior:

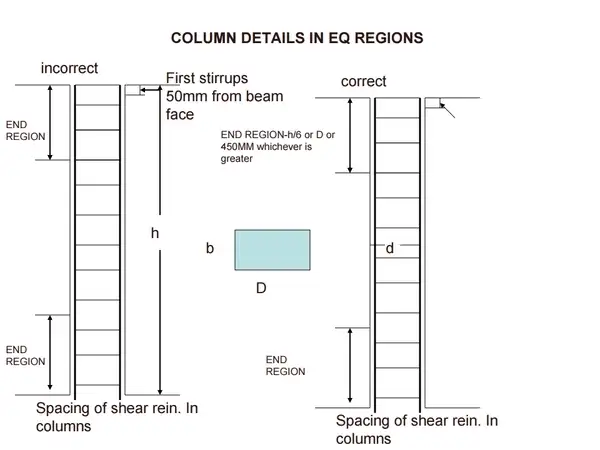

Column Details in EQ-Region:

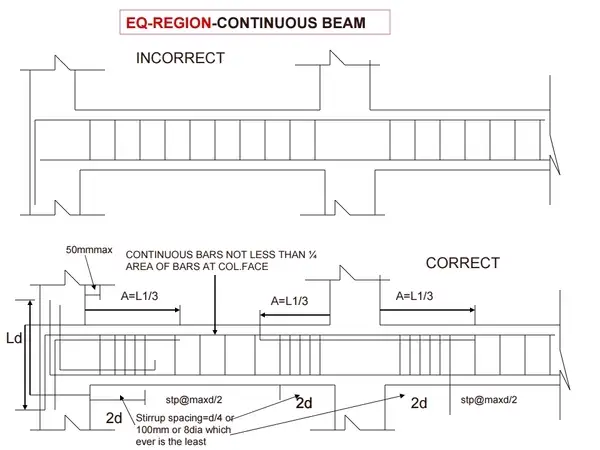

Eq-Region Continuous Beam:

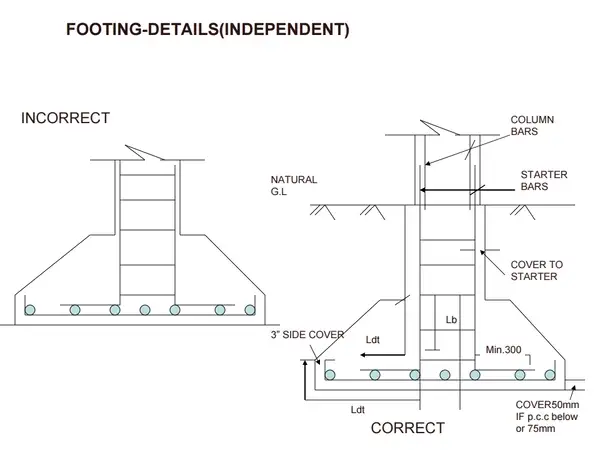

Footing Details (Independent):

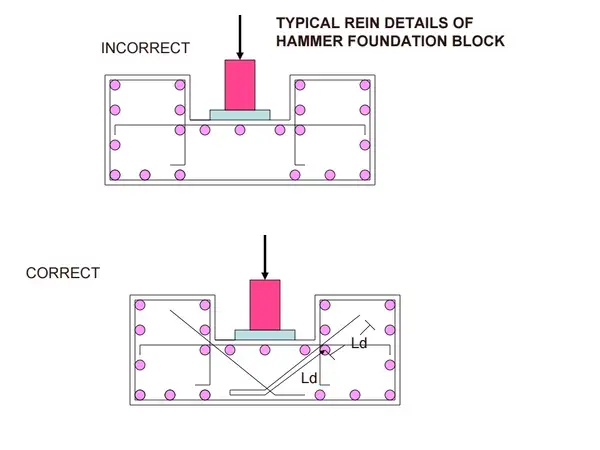

Typical Reinforcement Detail of Hammer Foundation Block:

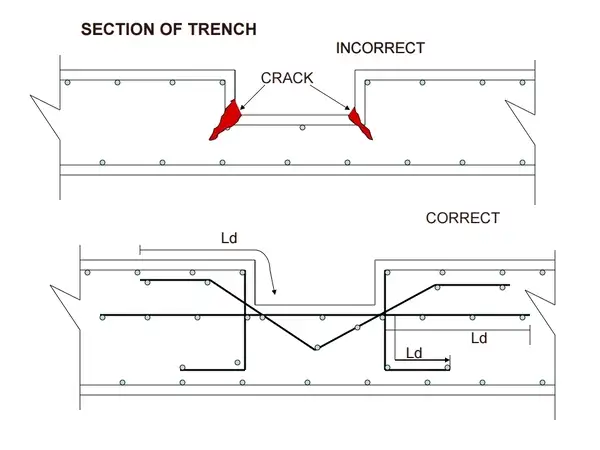

Section of Trench:

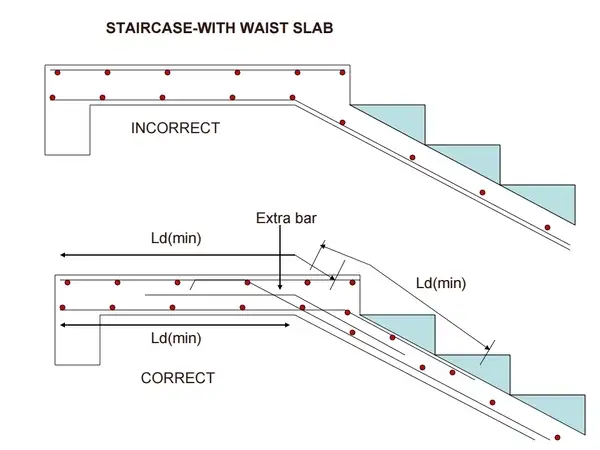

Staircase with Waist Slab:

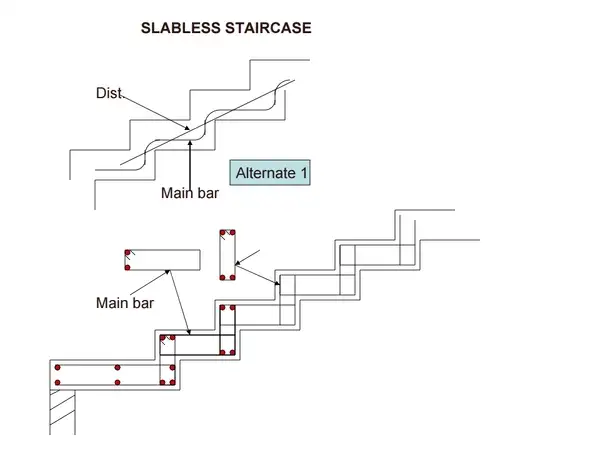

Slab-Less Staircase | Alternate 1:

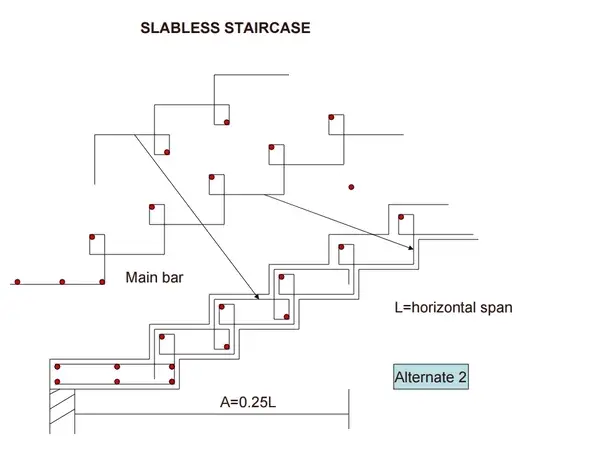

Slab-Less Staircase | Alternate 2:

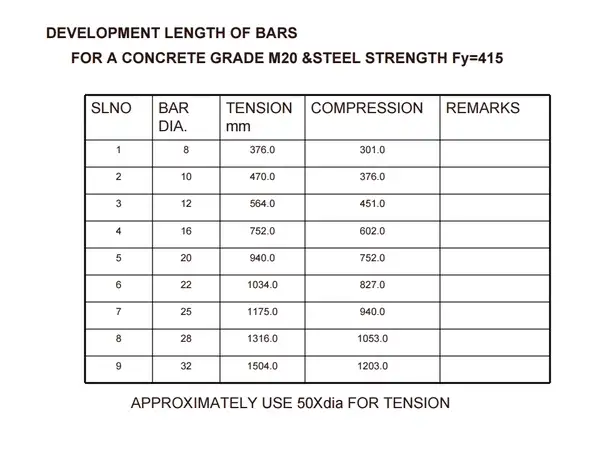

Development Length of Bars:

Conclusion:

Full article on Reinforcement Detailing of RCC Members | RCC Beam | RCC Column | RCC Footing | RCC Staircase | Development Length of Bars | RCC Foundation. Thank you for the full reading of this article in “The Civil Engineering” platform in English. If you find this post helpful, then help others by sharing it on social media. If you have any question regarding article please tell me in comments.

6 Comments

thank you so much.

Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar

Thank Sr so much.

Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar

Thank you so much.

Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar