Lap Length in Reinforcement Concrete Structures | Column, Beam and Slab | Calculation of Lap Length | Rebar Splicing Standards | What is Overlapping or Lap Length in RCC ?

In this Article today we will talk about the Lap Length in Reinforcement Concrete Structures | Column Beam and Slab | Calculation of Lap Length | Rebar Splicing Standards | Over Lapping or Lap Length in RCC.

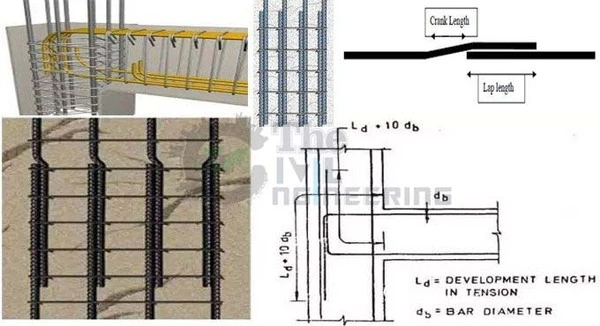

Due to the limited length of bar, lapping of bars are required in a member of more than 12m in length or where length of bar required is more than 12m.

Lap Length:- Length of bar required to transfer the stress safely.

or

Lap Length:- Overlapping Length or Lap Length is provided for maintain the continuity of bars in order to safely transfer the load from one bar to another bar. It depends on the Grade of Concrete, grade of steel and dia. of bar.

OTHER POSTS:

-

Bar Bending Schedule Basic Formulas | BBS Formula | What is BBS

-

Bar Bending Schedule of RCC Beam | BBS of RCC Beam

-

How to Calculate the Cutting Length of Spiral Bar or Helix Bar | BBS

- Gable Roof | Types of Gable Roof | Parts Advantages & Disadvantages

Why Do We Provide Lap Length ???

Reinforcement steel is generally manufactured for a standard 12m length. During construction when steel is to be provided for a length greater than 12m, the bars are lapped to maintain continuity in the reinforced structures. This lap length varies in different RCC structures and generally lies between 30d (d=bar diameter) to 55d depending on the design and grade.

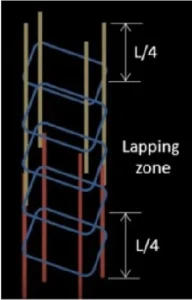

How Much Lap Length is Provided in Column ???

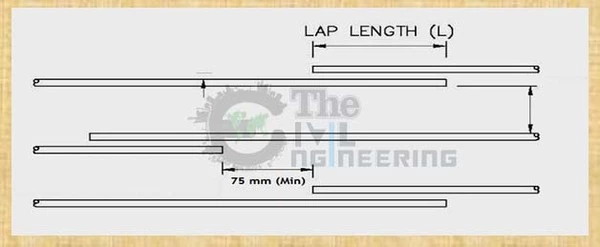

As per IS Code 456-2000 overlapping length should not be less than 75mm. Lapping should be avoided in tensile zone of construction members. In case of column generally we take 24d – 40d where ‘d’ is dia of bar.

Important Point Should be Remember for Column Lap Length:

- Lapping should be provided at the center of column because bending moment at mid point is zero so try to lap at mid point.

- Lapping of bars should be provided alternately. Lap should not be given at same point because buckling may occur.

- Lateral ties should be provided closely spaced in Lapping zone.

- Due to maximum stress we can’t lap at column/beam/slab joint. Lapping should not be given at L/4 distance from top and bottom of the slab.

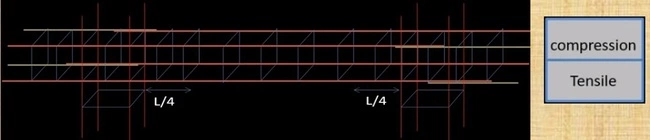

How Much Lap Length is Provided in Beam ???

In case of beam we generally use 24d for compression zone and 45d for tensile/tension zone.

Important Point Should be Remember for Beam Lap Length:

- Lapping (24d) in top bars avoided L/3 distance from both end. For top bar lapping should be at mid span.

- Lapping (45d) in bottom bars lap should be provided at column junction or L/4 distance from column face but should not be in mid span of beam.

- Stirrups should be closely spaced near the columns and lose/normal at mid span.

- Lapping of bars should be alternately provided.

How Much Lap Length is Provided in Slab ???

In case of slab we use lap length 50d where ‘d’ is dia of bar.

Important Point Should be Remember for Slab Lap Length:

- RCC slabs function is similar to beams if the slab is designed as one way. It is ideal to lap bars at point of least bending moment or at points of contra flexure.

- Practically laps are provided beyond L/5 to L/3 ( L being the effective span) from a support for bars at bottom of slab. The top bars are generally short and no laps are necessary. However at no point the lapped bars shall exceed one third of the total bars.

- Bars will be considered staggered if end to end distance b/w laps is at least (lap length +75mm)

Conclusion:

Full article on Lap Length in Reinforcement Concrete Structures | Column Beam and Slab | Calculation of Lap Length | Rebar Splicing Standards | Over Lapping or Lap Length in RCC.. Thank you for the full reading of this article in “The Civil Engineering” platform in English. If you find this post helpful, then help others by sharing it on social media. If you have any question regarding article please tell me in comments.

7 Comments

Hi Engr Raja. I’m an engineering student in Cameroon. I will like to follow you online for studies. Can that be possible?

yes u can follow me through this website or social media, Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar

dia of Steel 16 mm and use of concrete mix design m55 , find out the laping lengh.

Thank u sir…..am very happy to meet with u.

Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar

Thanks for your article much educative, follow u from Kenya

Thanks for the comments please visit more articles by clicking on “All Posts” tab of the Menu Bar