Rebar Bending Schedule of RCC Beam | BBS of Beam

In this Article today we will talk about the Bar Bending Schedule of RCC Beam | BBS Formulas | BBS of Beam | RCC Beam Calculations | Cutting Length of Beam Reinforcement | Quantity Surveyor | Estimation and Costing.

Bar Bending Schedule of RCC beam, commonly referred to as BBS” is a comprehensive list that describes the location, mark, type, size, length and number, and bending details of each bar or fabric in A reinforcement Drawing of a Structure.

This process of listing the location, type and size, number of and all other details is called “Scheduling”. In context of Reinforcement bars, it is called bar scheduling. In short, Bar Bending Schedule is a way of organizing rebars for each structural unit, giving detailed reinforcement requirements. BBS Formulas

General guidelines to be followed in preparing for BBS:

Here are some general guidelines for creating a bar bending schedule to follow:

- Study the Structural Drawings: Study the structural drawings to determine the size, shape, and placement of the reinforcement bars needed for the project.

- Select a Format: Select a BBS format that is simple to read and clearly identifies each bar, such as a tabular or shape-coded format.

- Determine the Rebar: Determine the kind, size, and shape of reinforcement bars needed for each project structural component.

- Calculate the quantity needed by adding up the required length, weight, and number of bars for each size and shape.

- Provide Bending Details: Provide bending details for each bar, such as the amount of bend, the bend’s radius, and the bend’s location.

- Provide a reference to the structural drawings, such as grid lines, column numbers, or beam numbers, to indicate the location of each bar.

- Based on their length, size, shape, and type, the bundles of bars should be marked with distinct reference numbers.

- Before finalizing the BBS, it should be reviewed for accuracy and completeness.

You can make sure that your bar bending schedule is accurate, comprehensive, and complies with the construction project’s requirements by adhering to these rules.

How Bar Bending Schedule is used in construction projects:

The Bar Bending Schedule (BBS) is an essential tool in the construction industry, particularly in reinforced concrete construction. The BBS is used to ensure that the correct amount and type of rebar is used in the construction project, and to help with the efficient placement of the rebar during the construction process. Here are some ways the BBS is used:

-

Quantity Estimation: The BBS is used to estimate the quantity of reinforcement required for a construction project. This helps to ensure that the right amount of materials is ordered and that there is no shortage or excess of materials.

-

Fabrication: The BBS is used to create cutting and bending schedules that are used by the fabricator to prepare the reinforcement. The schedules provide detailed information about the length, size, shape, and bending requirements for each bar.

-

Placement: The BBS is used to guide the placement of the reinforcement on the construction site. The schedule indicates the location of each bar on the structural drawings, making it easier for the contractor to ensure that the rebar is placed in the correct position.

-

Quality Control: The BBS is used to ensure that the reinforcement is fabricated and placed correctly. The schedule provides a reference for checking the length, size, shape, and bending requirements for each bar, helping to ensure that the work is done correctly.

Overall, the BBS is an essential tool in the construction industry, helping to ensure that the reinforcement is fabricated and placed correctly, and that the project is completed on time and within budget.

OTHER POSTS:

-

How To Find Out The Cutting Length Of Main Bars and Circular Rings

-

Cutting Length Of Triangular Stirrups | Cut Length Calculator

-

How to Calculate Cutting Length of Rectangular Stirrups

Bar Bending Schedule is used by the:

- Detailer

- person checking the drawing

- contractor who orders the reinforcement

- organization responsible for fabricating the reinforcement

- steel fixer

- clerk of works or other inspector

- the quantity surveyor

A quantity surveyor is in charge of project costing and operation estimation. High levels of accuracy are necessary for this kind of surveying. The quantity surveyor can consolidate the necessary number of bars for each type of bar with the help of a bar bending schedule, or BBS.

As a result, the quantity of steel reinforcement can be estimated, and the cost requirements for steel or reinforcement work follow. Therefore, the contractor who places the order for the reinforcements also uses BBS. The weight of the steel that was purchased determines the unit cost of the reinforcement.

To ensure that the reinforcement work on the job site is in accordance with the design requirements as shown in the drawings, the clerk of works and other inspectors consult the BBS. The steel fixers use it as a frame of reference firsthand. The quantity and type of bars required for a structural member or unit can be easily noted by them.

In essence, the Bar Bending Schedule incorporates all pertinent reinforcement-related data used by experts at various construction-related stages, from procurement to completion.

How to Prepare BBS ?

- Necessary Columns

- Bar number

- Bar Mark Reference

- Bar shape

- Diameter

- Spacing

- Length of bar

- Cutting Length

- Number of bars

The structural unit’s reinforcement drawings contain the majority of the information in a BBS. Simply by looking at the drawings, which will have detailed dimensions, rebar shape, diameter, length, and spacing are directly entered in the schedule.

Number of bars:

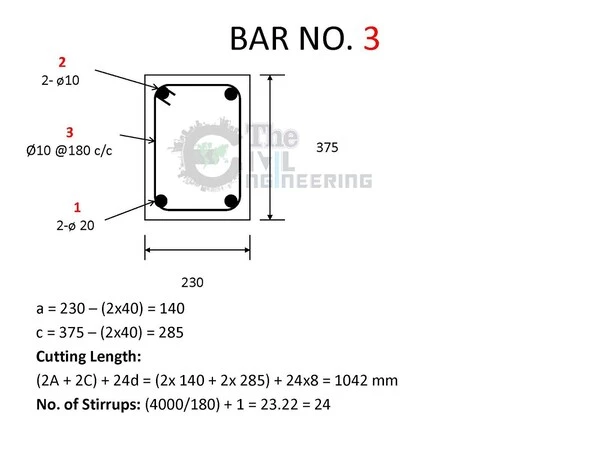

Suppose the spacing of stirrups is 150 c/c and the length along which they are placed is 6800 mm (6.8m), we can find the number (Nos) of bars by the formula below

[ Length / Spacing ] + 1 = number of bars

[ 6800 / 150 ] + 1 = 46.33

In this case, we always round up. Hence, we require 47 stirrups.

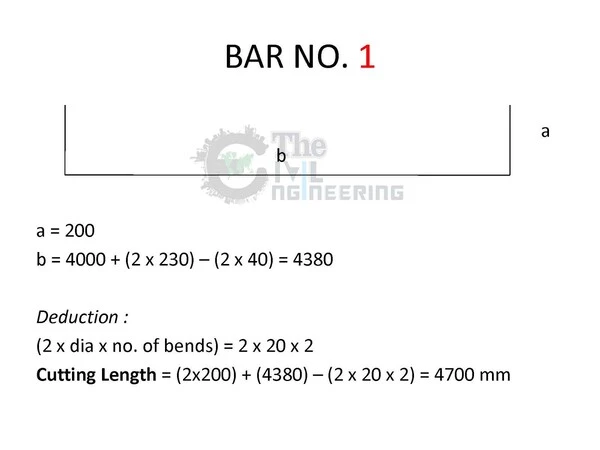

Cutting Length:

We must remember than steel is ductile in nature and is subject to elongation. Hence, the length of a rebar is increased when bends or hooks are introduced. Hence, certain deductions are needed to offset this increase in length.

Cutting Length of rebar = True Length of a bar – Deductions

For 45 degree

Cutting length of rebar = Total length – 1 x Dia of bar x No. of bends

For 90 degree

Cutting length of rebar = Total length – 2 x Dia of bar x No. of bends

For stirrups:

90 degree hook:

Length of stirrup = (2A + 2B) + 20 x dia

135 degree hook:

Length of stirrup = (2A + 2B) + 24 x dia

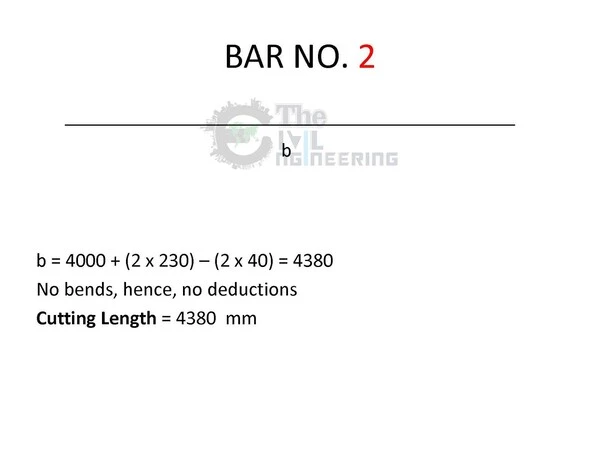

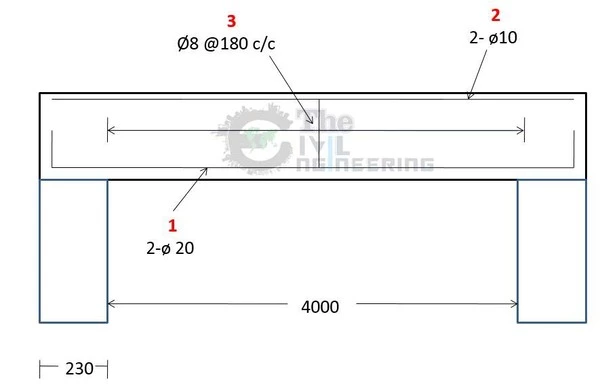

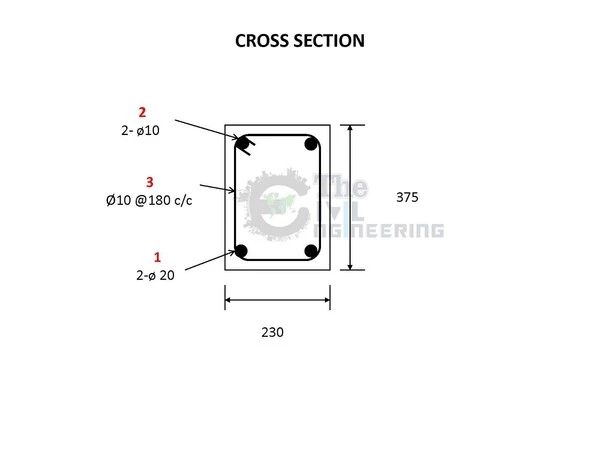

Example BBS of RCC BEAM Calculation:

Conclusion:

Full article on Bar Bending Schedule of RCC Beam | BBS Formulas | BBS of Beam | RCC Beam Calculations | Cutting Length of Beam Reinforcement | Quantity Surveyor | Estimation and Costing. Thank you for the full reading of this article in “The Civil Engineering” platform in English. If you find this post helpful, then help others by sharing it on social media. If you have any question regarding article please tell me in comments.