How to Calculate Cutting Length Of Triangular Stirrups | Cut Length Calculator | Cutting Length of Stirrups | Hook Length of Stirrups

In this article we will discuss about the Cutting Length Of Triangular Stirrups | Cut Length Calculator | Cutting Length of Stirrups | Hook Length of Stirrups | Bar Bending Schedule Circular Stirrups | Diamond Stirrups | Square Stirrups | Rectangular Stirrups | Helical Stirrups | 2 4 6 Legged Stirrups

Bar Bending Schedule, commonly referred to as “BBS” is a comprehensive list that describes the location, mark, type, size, length and number, and bending details of each bar or fabric in a Reinforcement Drawing of a Structure.

This process of listing the location, type and size, number of and all other details is called “Scheduling”. In context of Reinforcement bars, it is called bar scheduling. In short, Bar Bending Schedule is a way of organizing rebars for each structural unit, giving detailed reinforcement requirements.

Cutting Length Of The Triangular Stirrups Formula:

This construction video tutorial will teach you how to calculate the cutting length of triangular stirrup. Cut

The length of the column is given as 600 mm and width is given as 500 mm. Diameter (d) of the stirrup is given as 8 mm. Clear cover for both sides is taken as 40 mm. Center to center length of the main bars is taken as a (512 mm) and center to center width is taken as b (412 mm). Circular Stirrups | Diamond Stirrups | Square Stirrups | Rectangular Stirrups | Helical Stirrups | 2 4 6 Legged Stirrups

OTHER POSTS:

-

How To Calculate Cutting Length of Bent Up Bars

-

How to Calculate the Unit Weight of Steel Bars

-

How to Make Bar Bending Schedule for Pile Foundation Reinforcement

Given below, the process, how the above center to center values are derived:-

a = 600 – (2 x 40) – (2 x 4) (4 means half of diameter 8 mm) = 512 mm

b = 500 – (2 x 40) – (2 x 4) (4 means half of diameter 8 mm) = 412 mm

The following formula is used to find out the cutting length

= (2 x H) + a + (2x10xd) (as there are two hooks and length of one hook is 10 mm; dia means dia of stirrups) – (4x3xd) (there are 4 bends and each bend is located at 90 degree angle and for each bend 3d has been deducted, here dia means dia of stirrups)

Pythagorean theorem is used to find out the value of H. It is a basic relation in Euclidean geometry between the three sides of a right triangle. It expresses that the square of the hypotenuse (the side located reverse of the right angle) is identical to the sum of the squares of the other two sides. Cutting Length of Stirrups

How to Find the Cutting Length Of Triangular Stirrups (Example):

-

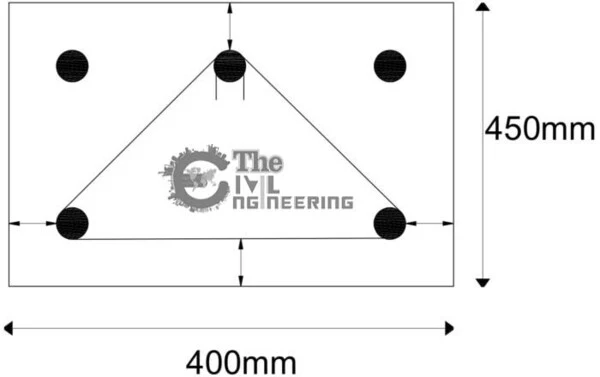

Considered the Column size 400mm x 450mm

- Adopting Dia of Bar used for stirrups is d = 8mm

- Deducting the concrete cover 25mm from all sides. Hook Length of Stirrups

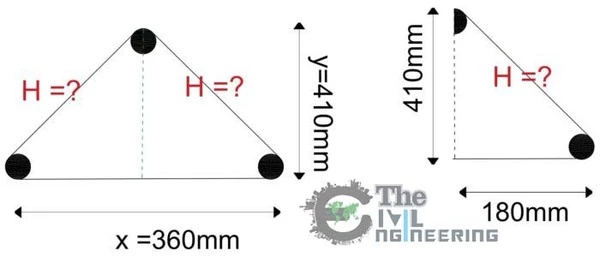

x = 400-20-20 = 360mm

y = 450-20-20 = 410mm

From Pythagorean theorem,Hypotenuse2=(Opposite)2 + (Adjacent)2

Cutting Length Of Triangular Stirrups | Cut Length Calculator look at 2nd triangle in above image

H2=(x/2)2 + y2

H2=1802 + 4102 => = √(447)2 = 447mm

The total length of stirrup till now = 2 x H + 360 = 2 x 447 + 360 = 1254mm -

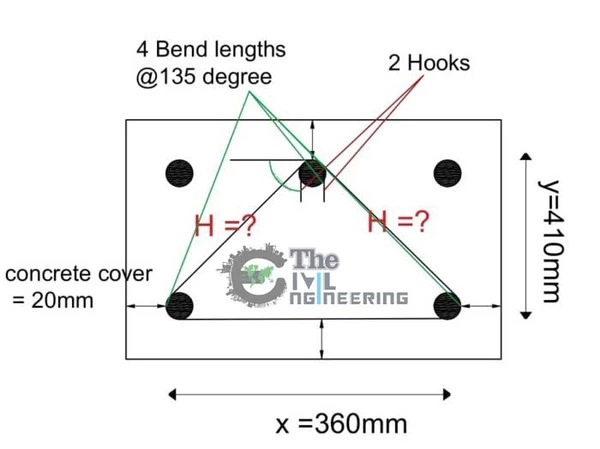

Total Hook Length of Stirrups:

There are two hooks which means 9d+9d= 18d

-

Total length of Bends:

There are 4 bends which are bent at an angle of 1350

Total bend length =4 x 1350 Bend length= 4 x 3d = 12d= 12 x 8 = 96mm

Total Cutting length of Triangular Stirrup = Perimeter of Triangle + Total Hook length – Total Bend Length

= 1254+18d – 12d = 1302mm = 1.3m

In order to learn how the value of H is derived, watch the above construction video tutorial

Advantages of Bar Bending Schedule:

Bar bending schedule provides details of reinforcement cutting and bending length. Advantages of bar bending schedule is when used along with reinforcement detailed drawing improves the quality of construction, cost and time saving for concrete construction works.

Advantages of bar bending schedule in concrete construction are:

1. When Bar bending schedule is available, cutting and bending of reinforcement can be done at factory and transported to site. This increases faster execution at site and reduces construction time and cost due to less requirement of workers for bar bending. Bar bending also avoids the wastage of steel reinforcement (5 to 10%) and thus saves project cost.

2. Using bar bending schedule for when used for Fe500, it saves 10% more steel reinforcement compared to fe415.

3. It improves the quality control at site as reinforcement is provided as per bar bending schedule which is prepared using the provisions of respective detailing standard codes. Circular Stirrups | Diamond Stirrups | Square Stirrups | Rectangular Stirrups | Helical Stirrups | 2 4 6 Legged Stirrups

4. It provides the better estimation of reinforcement steel requirement for each and every structural member which can be used to compute overall reinforcement requirement for entire project.

5. It provides better stock management for reinforcement. Steel requirement for next phase of construction can be estimated with accuracy and procurement can be done. This prevents stocking of extra steel reinforcement at site for longer time, preventing corrosion of reinforcement in case of coastal areas. It also prevents shortage of reinforcement for ongoing work by accurate estimation and thus concrete construction works can proceed smoothly.

6. Bar bending schedule is very much useful during auditing of reinforcement and provides checks on theft and pilferage.

7. Bar bending schedule can be used for reinforcement cutting, bending and making skeleton of structural member before it can be placed at the required position. Other activities such as excavation, PCC etc can proceed parallel with this activity. So, overall project activity management becomes easy and reduces time of construction. It becomes helpful in preventing any damages due to construction time overrun.

8. It provides benchmarks for quantity and quality requirements for reinforcement and concrete works.

9. Bar bending schedule provides the steel quantity requirement much accurately and thus provides an option to optimize the design in case of cost overrun. Circular Stirrups | Diamond Stirrups | Square Stirrups | Rectangular Stirrups | Helical Stirrups | 2 4 6 Legged Stirrups

10. It becomes easy for site engineers to verify and approve the bar bending and cutting length during inspection before placement of concrete with the use of bar bending schedule and helps in better quality control.

11. It enables easy and fast preparation of bills of construction works for clients and contractors.

12. The quantity of reinforcement to be used is calculated using engineering formulas and standard codes, so there is no option for approximate estimation of steel reinforcement.

13. With the use of bar bending schedule, mechanization of cutting and bending of reinforcement can be done, again reducing the cost and time of project and dependency on skilled labor requirement. It also improves the reliability on accuracy of bar cutting and bending.

14. When mechanized bar cutting and bending is used, the cost of reinforced concrete work per unit reduces and helps in cost optimization of construction project. Circular Stirrups | Diamond Stirrups | Square Stirrups | Rectangular Stirrups | Helical Stirrups | 2 4 6 Legged Stirrups

Conclusion:

Full article on Cutting Length Of Triangular Stirrups | Cut Length Calculator | Cutting Length of Stirrups | Hook Length of Stirrups | Bar Bending Schedule. Thank you for the full reading of this article in “The Civil Engineering” platform in English. If you find this post helpful, then help others by sharing it on social media. For More detail please see the above video tutorial further you have any question regarding article please tell me in comments.