Reinforcement Detailing of Reinforced Concrete Structures | Rebars Detailing | Standard Hooks | Minimum Bend Diameters | Surface Conditions of Reinforcement:

In this article we will discuss about Reinforcement Detailing of Reinforced Concrete Structures | Rebar Detailing | Standard Hooks | Minimum Bend Diameter | Surface Conditions of Reinforcement | Spacing and Placing of Reinforcement.

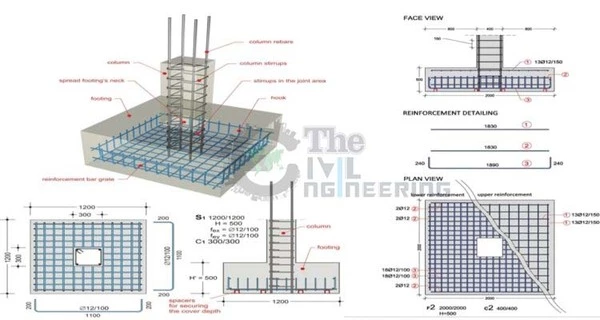

Reinforcement Detailing or Rebar detailing is the discipline of preparing ‘shop/placing’ drawings or shop drawings of steel reinforcement for construction. Architect/Engineers(A/E) prepare ‘Design Drawings’ that develop required strengths by applying rebar size, spacing, location, and lap of steel.

Standard Hooks:

The term “standard hook” as used in this Code shall mean one of the following:

- 180o bend plus an extension of at least 4 bar diameters, but not less than 65 mm at the free end of the bar. Rebar Detailing

- 90o bend plus an extension of at least 12 bar diameters at the free end of the bar.

- For stirrup and tie anchorage

For 16 mm φ bar and smaller, a 90o bend plus an extension of at least 6 bar diameters at the free end of the bar,- For 19 mm to 25 mm φ bars, a 90o bend plus an extension of at least 12 bar diameters at the free end of the bar,

- For 25 mm φ bar and smaller, a 135o bend plus an extension of at least 6 bar diameters at the free end of the bar,

- For closed ties and continuously wound ties, a 135o bend plus an extension of at least 6 bar diameters, but not less than 75 mm.

OTHER POSTS:

-

Difference Between Lap Length and Development Length

-

Asphalt Concrete Pavement Placement Requirements

-

Minimum Thickness of Structural Concrete Members or Elements

Minimum Bend Diameters:

The minimum diameter of bend measured on the inside of the bar, for standard hooks other than for stirrups and ties in sizes 10 mm φ through 16 mm φ, shall not be less than the values shown in Table below

For stirrups and tie hooks, inside diameter of bend shall not be less than 4 bar diameters for 16 mm φ bar and smaller. For bars larger than 16 mm φ, diameter of bend shall be in accordance with Table above.

Inside diameter of bend in welded wire reinforcement for stirrups and ties shall not be less than 4 bar diameters for deformed wire larger than MD40 and 2 bar diameters for all other wires. Bends with inside diameter of less than 8 bar diameters shall not be less than 4 bar diameters from nearest welded intersection. Spacing and Placing of Reinforcement

Bending:

Unless otherwise permitted by the engineer, all reinforcement shall be bent cold.

Reinforcement partially embedded in concrete shall not be bent in place, except as permitted by the engineer or as shown in the design drawings.

Surface Conditions of Reinforcement:

When concrete is placed, metal reinforcement shall be free from mud, oil, or other nonmetallic coatings that decrease bond. Epoxy‐coating of steel reinforcement in accordance with standards referenced in this code shall be permitted.

Metal reinforcement with rust, mill scale, or a combination of both, shall be considered satisfactory, provided the minimum dimensions (including height of deformations) and weight of a hand‐wire brushed test specimen are not less than applicable ASTM specification requirements.

Placing of Reinforcement:

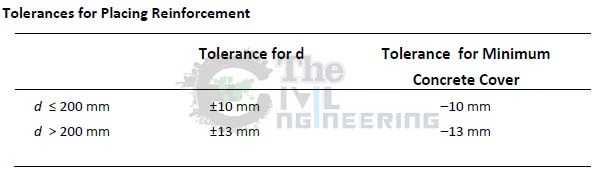

- Reinforcement shall be accurately placed and adequately supported before concrete is placed, and shall be secured against displacement within tolerances permitted in table below,

- Reinforcement shall be placed within the following tolerances unless otherwise specified by the engineer:

- Tolerances for depth d, and minimum concrete cover in flexural members, walls and compression members shall be as set forth in below table

- Notwithstanding the provision of (a) above, tolerance for the clear distance to formed soffits shall be minus 6 mm and tolerance for cover shall not exceed minus 1/3 the minimum concrete cover specified in the design drawings or specifications.

- Tolerance for longitudinal location of bends and ends of reinforcement shall be ± 50 mm, except at discontinuous ends of brackets and corbels, where tolerance shall be ± 13 mm and at discontinuous ends of other members, where tolerance shall be ±25 mm. The tolerance for concrete cover of shall also apply at discontinuous ends of members.

- Welded wire reinforcement (with wire size not greater than MW30 or MD30) used in slabs not exceeding 3 m in span shall be permitted to be curved from a point near the top of slab over the support to a point near the bottom of slab at midspan, provided such reinforcement is either continuous over, or securely anchored at support.

- Welding of crossing bars shall not be permitted for assembly of reinforcement unless authorized by the engineer.

Spacing of Reinforcement:

The minimum clear spacing between parallel bars in a layer shall be equal to one bar diameter, but not less than 25 mm, or 4/3 the maximum nominal size of coarse aggregate, whichever is larger.

Where parallel reinforcement is placed in two or more layers, bars in the upper layers shall be placed directly above those in the bottom layer with clear distance between layers not less than 25 mm.

For compression members, the clear distance between longitudinal bars shall be not less than 1.5 bar diameters nor 40 mm nor 4/3 the maximum nominal size of coarse aggregate.

Clear distance limitation between bars shall apply also to the clear distance between a contact lap splice and adjacent splices or bars.

In walls and one‐way slabs the maximum bar spacing shall not be more than three times the wall or slab thickness h nor 450 mm.

For two‐way slabs, maximum spacing of bars shall not exceed two times the slab thickness h nor 450 mm.

For temperature steel only, maximum spacing shall not exceed five times the slab thickness h nor 450 mm.

Bundled Bars

(a) Groups of parallel reinforcing bars bundled in contact to act as a unit shall be limited to four in any one bundle.

(b) Bundled bars shall be enclosed within stirrups or ties.

(c) Bars larger than 32 mm φ shall not be bundled in beams.

(d) Individual bars within a bundle terminated within the span of flexural members shall terminate at different points with at least 40db stagger.

(e) Where spacing limitations and minimum concrete cover are based on bar diameter db, a unit of bundled bars shall be treated as a single bar of a diameter derived from the equivalent total area.

Conclusion:

Full article on Reinforcement Detailing of Reinforced Concrete Structures | Rebar Detailing | Standard Hooks | Minimum Bend Diameter | Surface Conditions of Reinforcement | Spacing and Placing of Reinforcement. Thank you for the full reading of this article in “The Civil Engineering” platform in English. If you find this post helpful, then help others by sharing it on social media. If you have any question regarding article please tell me in comments.